Many people don’t know the compressed air is applied in which applications,below we will introduce some main industries of the air compressor applications:

1.The compressed air of maglev turbo compressor can be used as the source of motivation:

-The compressed air can drive cylinder for pneumatic equipment

-The compressed air of industrial air compressor can be used for air Blow or inflate:

-such as tire inflating, blow molding, pipe blowing, bottle blowing, reactor stirring, silk blowing and weaving shuttle, etc.

-The compressed air of air compressor for sale can be used for Ventilation:

-To increase air underground in tunnels and mines

-The air of air compressor pump can be used for purging

-Machined parts cleaning, iron filings cleaning, dust blowing and workbench cleaning, etc.

-The air of high pressure air compressor can be used for spraying

-For Metal surface sandblasting, surface painting, etc.

-The air of oil free air compressor can be used for Pneumatic conveying(Powder conveying)

2.The compressed air of centrifugal air compressor can be used as the air source:

-Nitrogen/oxygen production

-The selective adsorption performance of molecular sieves for different molecules is used to achieve the final separation of nitrogen or oxygen.

-Compressed air of compressed air systems used in Fermentation industry

-Providing oxygen to microorganisms to produce the microorganisms.

3.The compressed air of industrial compressor applied in chemical fiber texturing:

-Texturing principle:

-Through the stretching and deformation process, the pre-oriented yarn produced by spinning (extensible and inelastic) is transformed into a stretch-textured yarn (with a certain elasticity) with relatively stable physical properties that can be directly used for weaving.

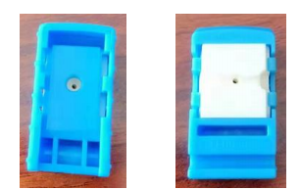

* The function of compressed air which is produced by electric air compressor:

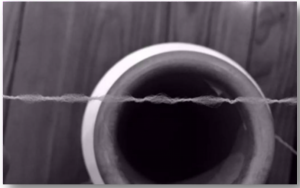

-Regular knots are blown through the nozzle on the silk being produced. The compressed air first blows the silk strips loose, and then causes them to rotate and twist each other into a interlacing shape, called interlacing yarn.

Knowledges about chemical fiber texturing application:

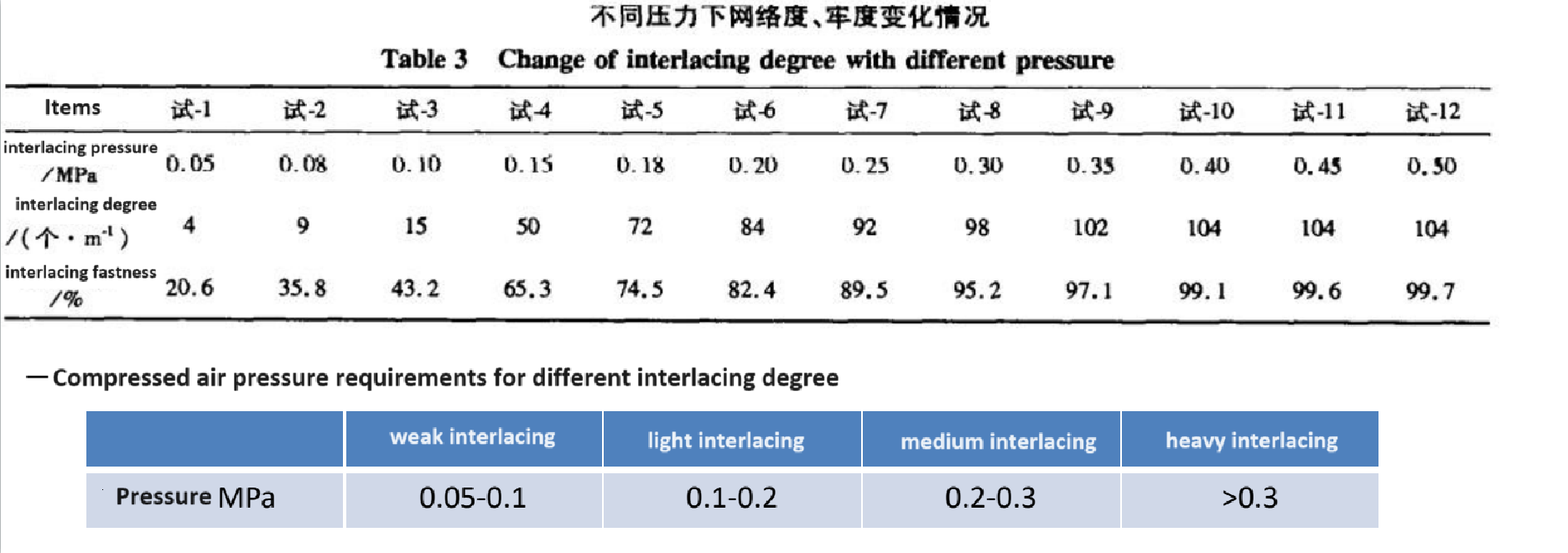

-Interlacing degree: -Interlacing degree refers to the number of nodes contained in a unit length of chemical fiber. The number of interlacing is mainly controlled by compressed air pressure. Of course, it is also related to the speed of the texturing machine and the draft ratio before and after the interlacing nozzle. -Generally divided into four degrees: weak interlacing, light interlacing, medium interlacing and heavy interlacing.

Compressed air and interlacing degree:

-During the interlacing process, when the compressed air pressure is low, as the compressed air pressure increases, the interlacing degree and interlacing fastness increase rapidly, and when the compressed air pressure increases to above 0.35MPa, the interlacing degree and interlacing fastness increases slowly until it stops increasing.

Customer application case-A chemical fiber factory:

-Product introduction:

-R&D and manufacture high-quality chemical fiber series. The production of polyester low-elastic yarn, polyester medium-elastic yarn, high-elastic yarn, PBT filament, etc. are widely praised.

-Texturing machine

-It has more than 100 advanced various texturing machines, among which Barmag is the main one.

-Air compressor machine

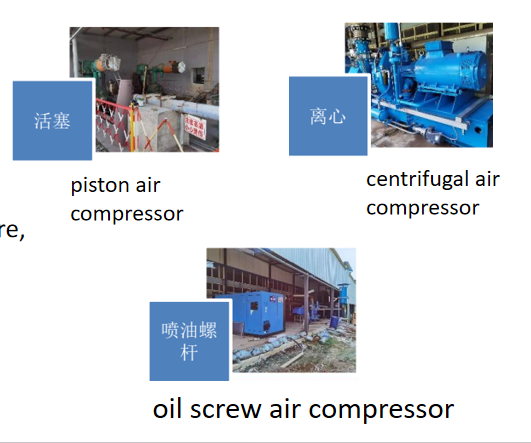

-There are about 30sets of different structure air compressors, 2/3 of which are low-pressure air compressors

-There are 4sets of low-pressure air compressors of piston structure, 1 centrifugal structure, and the others are oil-injected screw compressor.

-The low-pressure injection screw air compressor has two pressures: 2barg and 3barg. The actual pressure is 1.7barg and 2.3barg.

-Low-pressure injection screw manufacturers include Unitex, Kaishan and Zhigao; the centrifugal air compressor is Titanium brand; the piston air compressor is Nanya brand.

The above information is the brief introduction of the air compressor pump applications in some industries,there is more other industries need to use the high pressure compressors and lower pressure compressors.For now,RAETTS maglev centrifugal turbo compressor is totally oil-free and quiet.Energy-saving rate can be 10-20% more than traditional screw air compressor and centrifugal air compressor. Pls feel free to contact with RAETTS team if you need air compressor solutions.