Introduction

In the quest for increased efficiency and reduced energy consumption, industries are continually seeking advanced technologies to optimize their operations. One such innovation is the energy-saving maglev turbo blower. This cutting-edge equipment leverages magnetic levitation (maglev) technology to deliver superior performance while significantly reducing energy usage. This article explores the benefits, applications, and technical aspects of maglev turbo blowers in industrial settings.

What is a Maglev Turbo Blower?

Definition

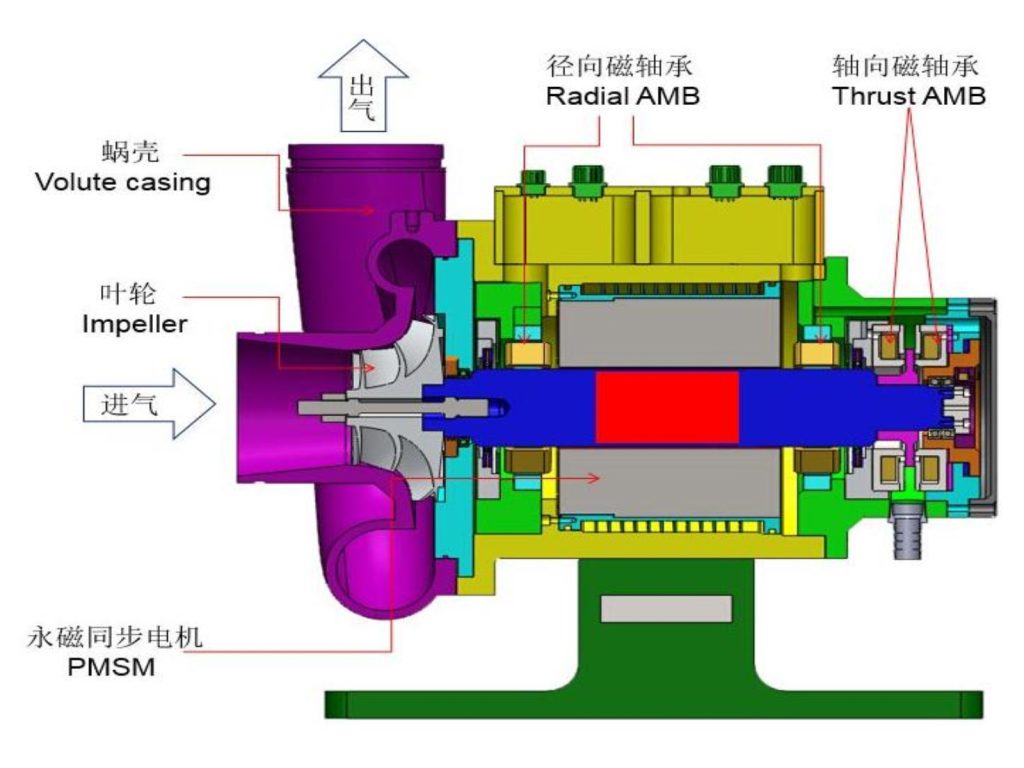

A maglev turbo blower is a high-efficiency air blower that uses magnetic levitation to suspend the blower’s impeller, eliminating mechanical contact and friction. This technology results in reduced energy consumption, lower maintenance costs, and enhanced operational reliability.

How It Works

Maglev turbo blowers utilize magnetic bearings to levitate the impeller shaft. An electric motor drives the impeller, which compresses air and delivers it at high pressures. The absence of mechanical bearings eliminates friction losses, resulting in higher efficiency and longer operational life.

Benefits of Maglev Turbo Blowers

Energy Efficiency

Maglev turbo blowers are designed to operate at high efficiencies, often exceeding 90%. The elimination of mechanical friction reduces energy losses, making these blowers significantly more energy-efficient compared to traditional blowers. This can lead to substantial energy savings in industrial applications.

Low Maintenance

The absence of physical contact between moving parts reduces wear and tear, resulting in lower maintenance requirements. Traditional blowers with mechanical bearings require regular lubrication and replacement, whereas maglev turbo blowers do not, leading to reduced downtime and maintenance costs.

Operational Reliability

Maglev turbo blowers offer high reliability due to their robust design and lack of mechanical wear. They can operate continuously with minimal risk of failure, making them ideal for critical industrial processes where reliability is paramount.

Noise Reduction

Maglev technology operates more quietly than traditional blowers. The elimination of mechanical friction and the smooth operation of the magnetic bearings result in significantly lower noise levels, creating a more pleasant working environment.

Environmental Impact

By reducing energy consumption and maintenance needs, maglev turbo blowers contribute to a lower carbon footprint. Their high efficiency and long service life make them a sustainable choice for industrial applications.

Industrial Applications of Maglev Turbo Blowers

Wastewater Treatment

Maglev turbo blowers are extensively used in wastewater treatment plants for aeration processes. Their high efficiency and reliability ensure consistent oxygen supply to the biological treatment processes, enhancing the overall efficiency of the wastewater treatment.

Chemical Processing

In the chemical industry, maglev turbo blowers are used for various processes requiring compressed air. Their ability to deliver consistent air flow at high pressures improves the efficiency and reliability of chemical processing operations.

Food and Beverage Industry

The food and beverage industry benefits from maglev turbo blowers in applications such as fermentation, drying, and packaging. The clean and oil-free air supplied by these blowers ensures the highest hygiene standards required in food processing.

Power Generation

Maglev turbo blowers are used in power plants for air and gas handling applications. Their high efficiency and low maintenance requirements make them suitable for the demanding environments of power generation facilities.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, maglev turbo blowers provide efficient air circulation and pressure control. Their quiet operation and energy efficiency are particularly beneficial in large commercial and industrial buildings.

Technical Features of Maglev Turbo Blowers

Magnetic Bearings

The core technology of maglev turbo blowers is the magnetic bearings that support the impeller shaft. These bearings use magnetic fields to levitate and stabilize the shaft, eliminating the need for physical contact and lubrication.

Variable Frequency Drive (VFD)

Maglev turbo blowers are often equipped with a Variable Frequency Drive (VFD) to control the motor speed and optimize the blower’s performance. The VFD allows for precise control of air flow and pressure, enhancing the efficiency of the system.

Advanced Control Systems

These blowers are integrated with advanced control systems that monitor and adjust operational parameters in real-time. This ensures optimal performance, energy efficiency, and protection against potential issues such as surges or overloads.

Compact Design

Despite their advanced technology, maglev turbo blowers are designed to be compact and lightweight. This makes them easy to install and integrate into existing industrial systems, saving valuable space and reducing installation costs.

Conclusion

The energy-saving maglev turbo blower represents a significant advancement in industrial air handling technology. Its superior energy efficiency, low maintenance requirements, and operational reliability make it an ideal choice for a wide range of industrial applications. By adopting maglev turbo blowers, industries can achieve substantial energy savings, reduce operational costs, and contribute to a more sustainable future. As technology continues to evolve, maglev turbo blowers are poised to become a standard in industrial efficiency and performance.