RAETTS, a leading turbo blower manufacturer, is renowned for its innovative and high-performance turbo blowers. In this article, we compare the technical details of RAETTS turbo blowers with those of Lone Star, another reputable manufacturer in the industry. Understanding these technical differences can help customers make an informed decision when selecting the right turbo blower for their specific needs.

Introduction to Turbo Blowers

Importance of Turbo Blowers

Industrial Applications

Turbo blowers are essential in various industrial applications, including wastewater treatment, aeration, pneumatic conveying, and HVAC systems. They provide high-efficiency air and gas movement, contributing to energy savings and operational efficiency.

Performance and Reliability

Choosing the right turbo blower is crucial for ensuring optimal performance, reliability, and cost-effectiveness. Technical specifications and design features play a significant role in determining the blower’s suitability for specific applications.

Technical Comparison: RAETTS VS Lone Star

Design and Construction

RAETTS Turbo Blowers

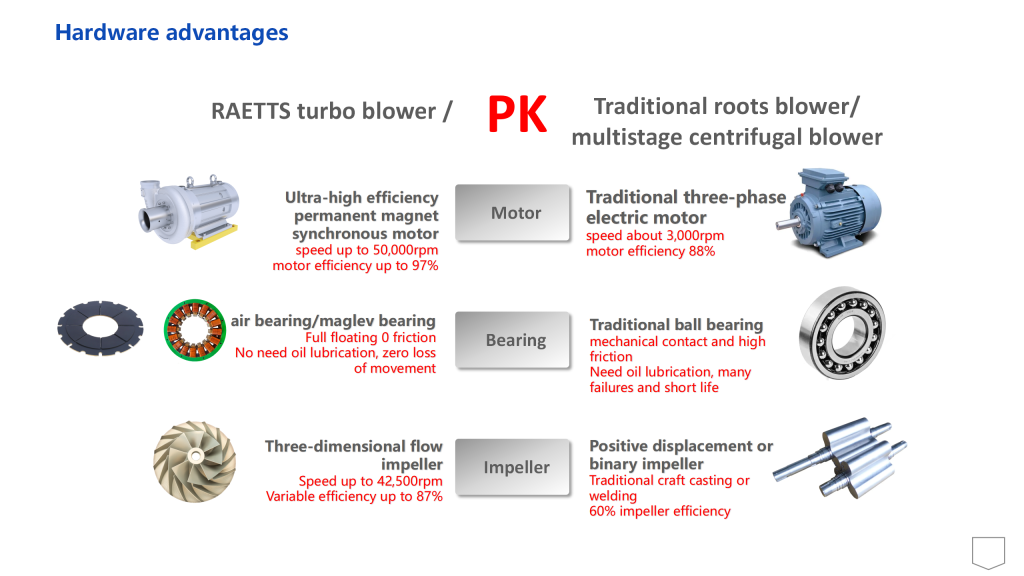

Advanced Aerodynamic Design

RAETTS turbo blowers feature an advanced aerodynamic design that enhances air flow efficiency and reduces energy consumption. The impellers are designed using computational fluid dynamics (CFD) to optimize performance.

High-Quality Materials

RAETTS uses high-quality, corrosion-resistant materials for the construction of its turbo blowers. The use of stainless steel and advanced composites ensures durability and long-term reliability.

Magnetic Levitation (Maglev) Technology

RAETTS incorporates magnetic levitation (maglev) technology in its turbo blowers, eliminating the need for physical bearings. This technology reduces friction, wear, and maintenance requirements while improving efficiency.

Lone Star Turbo Blowers

Robust Design

Lone Star turbo blowers are designed for robust performance in demanding industrial environments. Their construction focuses on durability and reliability, ensuring consistent performance over long operational periods.

Material Selection

Lone Star uses high-strength materials to withstand harsh operating conditions. The choice of materials ensures that their turbo blowers can handle various industrial applications with minimal wear and tear.

Oil-Free Bearings

Lone Star turbo blowers typically use oil-free air bearings, which reduce maintenance needs and improve operational efficiency. These bearings provide reliable performance without the lubrication requirements of traditional bearings.

Performance and Efficiency

RAETTS Turbo Blowers

High Efficiency

RAETTS turbo blowers are known for their high efficiency, achieving energy savings of up to 40% compared to conventional blowers. The aerodynamic design and maglev technology contribute to this superior efficiency.

Wide Operating Range

RAETTS turbo blowers offer a wide operating range, making them suitable for various applications. The blowers can handle different flow rates and pressures, providing flexibility in operation.

Low Noise Operation

Thanks to the maglev technology and advanced aerodynamic design, RAETTS turbo blowers operate with low noise levels, enhancing the working environment and reducing noise pollution.

Lone Star Turbo Blowers

Competitive Efficiency

Lone Star turbo blowers also deliver high efficiency, with energy savings comparable to those of RAETTS. The use of oil-free bearings and optimized impeller design contribute to their performance.

Stable Performance

Lone Star turbo blowers provide stable performance across a range of operating conditions. Their design ensures consistent airflow and pressure, making them reliable for continuous industrial use.

Noise Reduction Features

Lone Star incorporates noise reduction features in their turbo blowers, such as sound enclosures and vibration dampening. These features help minimize operational noise and improve workplace conditions.

Control and Monitoring

RAETTS Turbo Blowers

Advanced Control Systems

RAETTS turbo blowers are equipped with advanced control systems that allow for precise monitoring and adjustment of operating parameters. These systems include touch-screen interfaces and remote monitoring capabilities.

Real-Time Data Analytics

RAETTS offers real-time data analytics for performance monitoring. This feature enables proactive maintenance and optimization, ensuring the blowers operate at peak efficiency.

Lone Star Turbo Blowers

Integrated Control Panels

Lone Star turbo blowers come with integrated control panels that facilitate easy operation and monitoring. The control systems provide comprehensive data on blower performance and allow for adjustments as needed.

Diagnostic Tools

Lone Star includes diagnostic tools in their control systems, enabling users to identify and address potential issues quickly. These tools enhance the reliability and longevity of the blowers.

Maintenance and Reliability

RAETTS Turbo Blowers

Minimal Maintenance Requirements

RAETTS turbo blowers require minimal maintenance due to the maglev technology, which eliminates the need for physical bearings. This reduction in maintenance lowers operational costs and downtime.

Long Service Life

The use of high-quality materials and advanced technologies ensures a long service life for RAETTS turbo blowers. Their robust design and construction contribute to their reliability and durability.

Lone Star Turbo Blowers

Easy Maintenance

Lone Star turbo blowers are designed for easy maintenance, with accessible components and straightforward maintenance procedures. The use of oil-free bearings further simplifies maintenance tasks.

Reliable Operation

Lone Star’s focus on durable materials and robust design ensures reliable operation even in challenging environments. Their turbo blowers are built to withstand continuous use with minimal issues.

Conclusion

Both RAETTS and Lone Star offer high-quality turbo blowers with advanced features and reliable performance. RAETTS stands out with its maglev technology, high efficiency, and low maintenance requirements, making it an excellent choice for industries seeking cutting-edge solutions. Lone Star, with its robust design and competitive efficiency, provides a reliable alternative for various industrial applications.

Choosing the right turbo blower depends on specific application requirements, performance expectations, and operational priorities. RAETTS, as a leading turbo blower manufacturer, is committed to delivering innovative and efficient solutions that meet the diverse needs of our customers. Trust RAETTS for your industrial air and gas movement needs, and experience the benefits of advanced maglev turbo blower technology.