Pharmaceutical cleanrooms are the backbone of manufacturing processes in the pharmaceutical industry, where maintaining stringent environmental controls is crucial to ensuring product quality, safety, and compliance with regulatory standards. These controlled environments are designed to minimize contamination and maintain the necessary conditions for sensitive processes, such as drug formulation, sterilization, packaging, and biotechnology research.

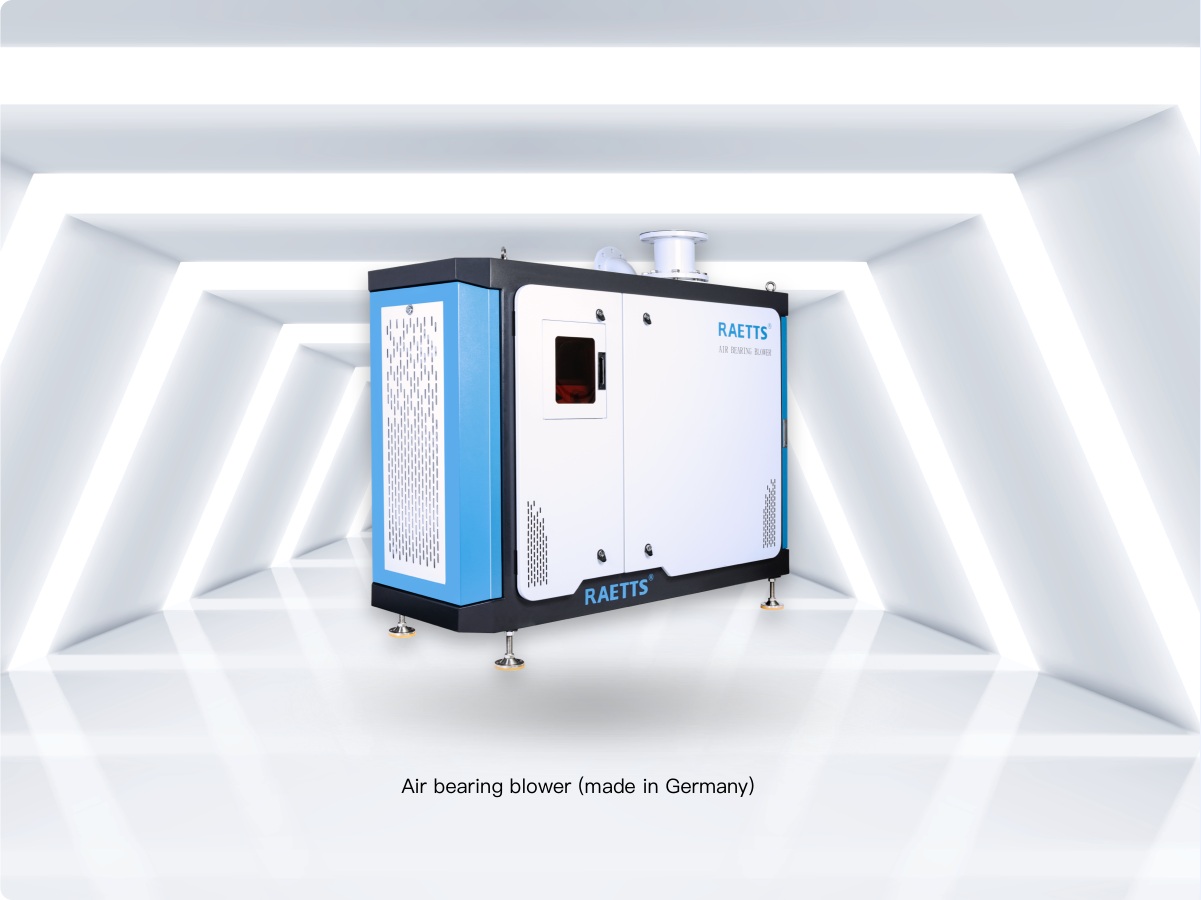

One of the key factors in maintaining the integrity of pharmaceutical cleanrooms is the ventilation system, which must deliver the right combination of airflow, filtration, and temperature control to prevent the introduction of harmful contaminants. In this context, air blower machines, particularly RAETTS turbo blowers, play an essential role in ensuring that these cleanrooms operate efficiently and maintain the required standards.

As a leading turbo blower manufacturer, RAETTS specializes in producing high-performance air blower machines that help pharmaceutical manufacturers optimize their cleanroom environments. In this article, we will discuss how RAETTS turbo blowers enhance cleanroom ventilation, improve energy efficiency, and ensure compliance with the strict requirements of the pharmaceutical industry.

The Importance of Cleanroom Ventilation in Pharmaceuticals

Pharmaceutical cleanrooms are highly regulated environments designed to ensure that airborne particles, microorganisms, and other contaminants do not compromise the manufacturing process or the integrity of the final product. Ventilation is one of the most critical factors in achieving this goal, as it directly influences air quality, temperature, humidity, and the rate of air changes within the room.

Key functions of cleanroom ventilation include:

- Airflow control: Ensuring that the air is consistently filtered and circulated throughout the cleanroom.

- Filtration: Utilizing high-efficiency filters like HEPA (High-Efficiency Particulate Air) or ULPA (Ultra-Low Penetration Air) filters to trap harmful particles.

- Pressure control: Maintaining the correct air pressure to prevent contaminants from entering the cleanroom.

- Temperature and humidity regulation: Controlling the temperature and humidity to optimize the conditions for both product quality and worker comfort.

In this context, RAETTS turbo blowers offer powerful, efficient, and reliable solutions for improving ventilation, controlling air quality, and reducing downtime in pharmaceutical cleanrooms.

1. Optimizing Airflow for Contamination Control

In a pharmaceutical cleanroom, maintaining consistent and controlled airflow is essential for preventing airborne contamination. Poor airflow distribution can lead to areas of stagnant air, which can increase the likelihood of particulate accumulation or the spread of contaminants.

RAETTS turbo blowers are designed to provide high-volume airflow with low-pressure operation, making them ideal for cleanroom applications. These blowers generate a steady stream of clean, filtered air that is efficiently distributed throughout the cleanroom. By maintaining the required air changes per hour (ACH), RAETTS turbo blowers help create a controlled environment where contaminants are continuously removed and replaced with fresh, filtered air.

The constant air circulation provided by RAETTS turbo blowers ensures that airborne particles, dust, and microorganisms are rapidly removed from the cleanroom, maintaining the stringent cleanliness levels required for pharmaceutical manufacturing.

RAETTS Tip: Ensure that RAETTS turbo blowers are integrated into your cleanroom ventilation system to maintain consistent airflow and minimize the risk of contamination.

2. Energy Efficiency for Cost-Effective Operations

Running a pharmaceutical cleanroom can be expensive due to the need for continuous ventilation, heating, cooling, and filtration. Traditional blower systems can be inefficient, consuming excessive amounts of energy to maintain optimal airflow and temperature levels. With the increasing emphasis on sustainability and cost control, energy-efficient solutions have become more important than ever.

RAETTS turbo blowers are designed with energy efficiency in mind, providing high airflow with minimal energy consumption. Unlike conventional blower systems, RAETTS turbo blowers use advanced aerodynamic technology to achieve optimal performance at lower power consumption levels. This translates to lower operational costs, reduced energy consumption, and a greener approach to running a cleanroom.

In addition, RAETTS turbo blowers feature variable-speed control, which allows you to adjust the blower’s output based on the current needs of the cleanroom. This dynamic airflow adjustment further reduces energy waste by ensuring that the system operates only at the necessary capacity.

RAETTS Tip: Using RAETTS turbo blowers in your pharmaceutical cleanroom can help you achieve energy savings while maintaining optimal air quality and airflow.

3. Maintaining Cleanroom Pressure and Air Quality

In a pharmaceutical cleanroom, maintaining the proper air pressure is essential to ensure that contaminants from adjacent rooms or external environments are kept out. Positive pressure is often used in controlled environments to prevent outside air from entering and potentially contaminating the cleanroom.

RAETTS turbo blowers play a critical role in regulating air pressure by providing the necessary constant airflow to maintain consistent pressure levels. By ensuring that the air is pushed out of the cleanroom at the correct rate, RAETTS turbo blowers help prevent airborne pollutants from infiltrating the space.

Moreover, RAETTS turbo blowers are equipped with advanced filtration systems, which remove particulates and microorganisms from the air before it enters the cleanroom. This dual-function of airflow management and filtration helps maintain the high air quality standards required for pharmaceutical manufacturing.

RAETTS Tip: Ensure that RAETTS turbo blowers are part of your cleanroom’s positive pressure system to maintain optimal air quality and prevent external contaminants from entering.

4. Enhanced Temperature and Humidity Control

In pharmaceutical manufacturing, both temperature and humidity must be carefully controlled to ensure product stability and quality. Variations in temperature or humidity can affect the chemical composition of products or lead to the growth of microorganisms, compromising the integrity of sensitive compounds.

RAETTS turbo blowers help maintain temperature and humidity levels by providing consistent airflow throughout the cleanroom. This uniform airflow promotes even temperature distribution, preventing hot or cold spots that could lead to inconsistencies in the environment.

By supporting HVAC systems, RAETTS turbo blowers also contribute to the regulation of humidity levels, helping to keep the cleanroom within the required range for optimal product conditions. Whether for sterilization processes, drug formulation, or biological research, maintaining the proper environmental conditions is crucial, and RAETTS turbo blowers play a key role in this process.

RAETTS Tip: Use RAETTS turbo blowers to enhance your HVAC system and ensure that temperature and humidity levels remain stable and within the required range for pharmaceutical production.

5. Improving Cleanroom Maintenance and Downtime Reduction

In pharmaceutical cleanrooms, minimizing downtime due to equipment failure or inefficiencies is crucial for maintaining continuous production. RAETTS turbo blowers are designed with durability and low-maintenance in mind, offering a longer lifespan compared to traditional blower systems. Their high reliability reduces the likelihood of breakdowns, ensuring that cleanrooms remain operational without frequent interruptions.

Moreover, RAETTS turbo blowers require less manual cleaning than traditional blower systems, as their design minimizes the accumulation of dust and particles in the motor and components. This helps reduce maintenance efforts and keeps the cleanroom system running smoothly with fewer interventions.

RAETTS Tip: With RAETTS turbo blowers, you can significantly reduce maintenance downtime and increase operational efficiency, keeping your cleanroom running at optimal performance levels.

Conclusion: Enhance Pharmaceutical Cleanroom Efficiency with RAETTS Turbo Blowers

In the pharmaceutical industry, cleanrooms are essential for ensuring the quality, safety, and compliance of manufactured products. The ventilation system, including air blower machines, plays a vital role in maintaining the necessary conditions for cleanroom operations. RAETTS turbo blowers are the ideal solution for enhancing cleanroom performance by ensuring consistent airflow, maintaining air pressure, and improving energy efficiency.

By choosing RAETTS turbo blowers for your cleanroom ventilation needs, you can achieve:

- Optimized airflow for contamination control.

- Energy savings and cost-effective operations.

- Improved temperature and humidity regulation for product stability.

- Reduced maintenance downtime and increased system reliability.

As a leading turbo blower manufacturer, RAETTS offers high-performance solutions that meet the stringent requirements of pharmaceutical cleanrooms, helping you maintain air quality, reduce operational costs, and ensure compliance with industry standards.

Contact RAETTS today to learn more about our turbo blower machines and how they can improve the efficiency and reliability of your pharmaceutical cleanroom operations.