Maintaining cleanliness and hygiene in industrial kitchens is essential for ensuring food safety, operational efficiency, and compliance with health regulations. Whether you’re running a restaurant, catering service, food processing plant, or a commercial kitchen, maintaining a high standard of cleanliness is non-negotiable. Air blower machines have become a critical part of modern kitchen cleaning practices, particularly when it comes to efficiently removing moisture, dust, grease, and food particles from surfaces and equipment.

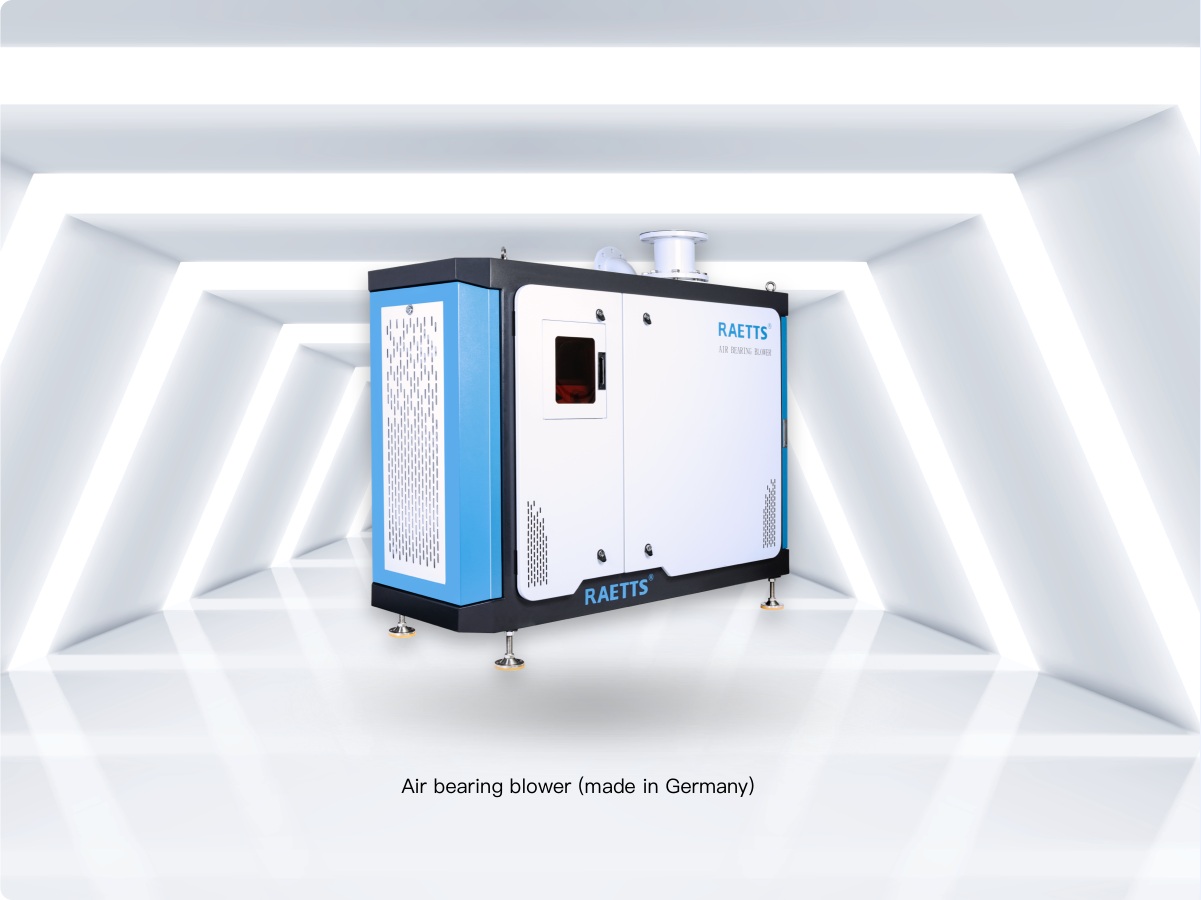

One of the best solutions for improving the cleaning process in industrial kitchens is the use of high-performance turbo blowers. RAETTS, a trusted turbo blower manufacturer, offers advanced air blower machines that are specifically designed to improve cleanliness and hygiene in commercial kitchens by optimizing airflow, removing excess moisture, and promoting faster drying of surfaces and equipment.

In this article, we will discuss the best practices for using RAETTS air blower machines to clean and maintain industrial kitchens effectively, highlighting how RAETTS turbo blowers can improve efficiency, hygiene, and operational safety.

The Challenges of Cleaning Industrial Kitchens

Industrial kitchens face a variety of cleaning challenges, including:

- Moisture accumulation: Cleaning tasks, such as washing dishes, cleaning surfaces, and mopping floors, often leave kitchens damp. Excess moisture can lead to the growth of bacteria, mold, and unpleasant odors.

- Grease buildup: Grease, oil, and food particles are common contaminants that accumulate on equipment, walls, floors, and ventilation systems. These materials can be difficult to remove and require effective cleaning systems.

- Dust and food particles: In busy kitchen environments, dust and food debris can accumulate on surfaces, equipment, and ventilation systems.

- Time constraints: Industrial kitchens often operate with tight schedules, and any delays due to inefficient cleaning can disrupt operations and lead to longer cleaning times.

RAETTS air blower machines are designed to tackle these challenges efficiently by providing high-volume, low-pressure airflow to dry surfaces quickly, remove moisture, and clean difficult-to-reach areas in a fraction of the time.

1. Using Air Blowers for Fast Drying and Moisture Removal

Excess moisture in kitchen environments can be a breeding ground for harmful bacteria and mold growth. Surfaces that are left wet, such as countertops, floors, and cooking equipment, can not only harbor contaminants but also create slippery hazards, increasing the risk of accidents in the kitchen.

RAETTS turbo blowers offer an effective solution for moisture removal by providing high-volume, concentrated airflow to rapidly dry wet surfaces, reducing the risk of contamination. The powerful airflow helps evaporate water from surfaces, drying them faster and more thoroughly than traditional drying methods.

Best Practices for Moisture Removal:

- Use RAETTS turbo blowers to dry large kitchen surfaces, such as countertops, tables, and cooking stations, quickly after washing.

- Direct the airflow at wet floors, especially in areas prone to water pooling, to avoid slip hazards.

- Use the blower to dry dishware and cooking utensils after cleaning, ensuring they remain hygienic and dry before being stored.

RAETTS Tip: For areas with persistent moisture buildup, use RAETTS turbo blowers in conjunction with a dehumidifier to further enhance drying and moisture control.

2. Removing Grease and Food Particles Efficiently

Grease buildup is a common challenge in industrial kitchens, particularly on cooking equipment, ventilation systems, and walls. Over time, grease can accumulate and harden, making it difficult to remove. RAETTS turbo blowers can help tackle this issue by using high-powered air to dislodge grease, food particles, and other contaminants from surfaces, equipment, and hard-to-reach areas.

The powerful airflow generated by RAETTS turbo blowers helps break down grease, making it easier to clean and remove during routine maintenance. By blowing air into equipment such as grills, fryers, and exhaust hoods, you can remove particulate matter that might otherwise require labor-intensive scrubbing or power washing.

Best Practices for Grease Removal:

- Use RAETTS turbo blowers to blow air through kitchen exhaust systems and ventilation hoods to clear out grease buildup that accumulates in hard-to-reach ducts and filters.

- Direct the blower at cooking equipment to remove oil, grease, and food particles between uses. This minimizes the risk of cross-contamination and improves the lifespan of equipment.

- Regularly clean wall surfaces and other high-traffic areas using RAETTS turbo blowers to eliminate grease and food debris after deep cleaning sessions.

RAETTS Tip: For best results, pair the RAETTS turbo blowers with grease-cutting cleaning agents during deep-cleaning tasks to break down stubborn grease before blowing it away.

3. Preventing Mold and Mildew Growth

Moist and damp environments, especially in areas with inadequate airflow, are conducive to the growth of mold and mildew. These fungi not only create unpleasant odors but can also pose serious health risks to kitchen staff and customers. By eliminating moisture from surfaces and improving air circulation, RAETTS air blower machines help prevent mold and mildew from developing in industrial kitchens.

Best Practices for Mold Prevention:

- Use RAETTS turbo blowers to circulate air and remove moisture from areas that are prone to mold growth, such as kitchen sinks, dishwashing stations, and cooling areas.

- After cleaning wet floors, direct the blower to ensure that the entire surface is dried evenly to prevent moisture accumulation in corners and cracks.

- Periodically use RAETTS turbo blowers to dry out hidden areas, such as behind equipment or under cabinets, where moisture can accumulate unnoticed.

RAETTS Tip: Position RAETTS turbo blowers near areas with poor ventilation, like corners or areas behind equipment, to ensure adequate airflow and minimize moisture buildup.

4. Cleaning Air Ducts and Ventilation Systems

Proper air quality is crucial in industrial kitchens, especially when it comes to removing cooking odors, smoke, and grease. Air ducts and ventilation systems must be regularly cleaned to ensure that they function efficiently and don’t accumulate harmful grease or particulate matter. RAETTS turbo blowers can be an effective tool for cleaning HVAC systems and air ducts in industrial kitchens, ensuring that air is properly circulated throughout the space.

The powerful airflow produced by RAETTS turbo blowers can help dislodge debris, dust, and grease particles from ductwork, helping to improve air quality and reduce the buildup of airborne contaminants.

Best Practices for Air Duct and Ventilation System Cleaning:

- Regularly use RAETTS turbo blowers to blow air through air ducts and ventilation systems to clear dust, grease, and particles that accumulate over time.

- Use the blower to dry out filters and exhaust systems after they have been cleaned, ensuring they stay free of moisture and contaminants.

- Perform routine checks on ventilation systems and use RAETTS turbo blowers to keep air circulating efficiently, preventing any clogs or grease buildup in the ducts.

RAETTS Tip: Schedule routine cleaning of your ventilation systems with RAETTS turbo blowers to maintain air quality and improve system efficiency.

5. Increasing Operational Efficiency and Reducing Downtime

One of the biggest concerns for industrial kitchen managers is the time and labor required for effective cleaning. Long cleaning periods can lead to downtime and disrupt kitchen operations, which can affect service delivery. RAETTS turbo blowers are designed to improve cleaning efficiency by dramatically reducing the time required to dry and clean surfaces, equipment, and kitchen areas.

By using high-powered airflow to speed up drying times and remove debris quickly, RAETTS turbo blowers help industrial kitchens reduce cleaning time and keep operations running smoothly. With fewer manual interventions and faster turnaround times, kitchens can operate at peak efficiency while maintaining the highest hygiene standards.

Best Practices for Efficiency:

- Use RAETTS turbo blowers to quickly dry floors, countertops, and dishware after cleaning, reducing the need for manual drying and cleaning.

- Direct airflow to hard-to-reach areas where debris and moisture often accumulate, reducing the need for deep scrubbing or extended cleaning sessions.

- Integrate RAETTS turbo blowers into routine cleaning schedules to maintain consistent hygiene and minimize time spent on each task.

RAETTS Tip: Implement RAETTS turbo blowers as part of your regular cleaning protocol to streamline kitchen maintenance and reduce downtime, improving overall operational efficiency.

Conclusion: Optimize Industrial Kitchen Cleaning with RAETTS Turbo Blowers

Industrial kitchens require constant cleaning and maintenance to ensure hygiene, food safety, and operational efficiency. RAETTS turbo blowers provide an innovative solution for tackling some of the most common challenges in industrial kitchen cleaning, including moisture removal, grease buildup, dust elimination, and drying.

By integrating RAETTS air blower machines into your kitchen cleaning practices, you can:

- Reduce cleaning time and increase efficiency.

- Minimize moisture-related issues like mold and mildew growth.

- Improve air quality by cleaning ventilation systems and removing grease buildup.

- Enhance safety by preventing slip hazards and maintaining dry surfaces.

If you’re looking to improve your kitchen’s cleanliness and operational efficiency, RAETTS turbo blowers offer high-performance solutions that can help you meet your cleaning goals. Contact RAETTS today to learn more about our turbo blower machines and how they can help you maintain a cleaner, safer, and more efficient industrial kitchen environment.