In the automotive industry, accurate diagnostics are crucial for identifying issues with vehicles and ensuring that they are repaired efficiently. From modern engine management systems to intricate electronic components, automotive diagnostics require not only advanced tools but also a clean and controlled environment. One essential piece of equipment that plays a significant role in both diagnostics and maintenance is the air blower machine.

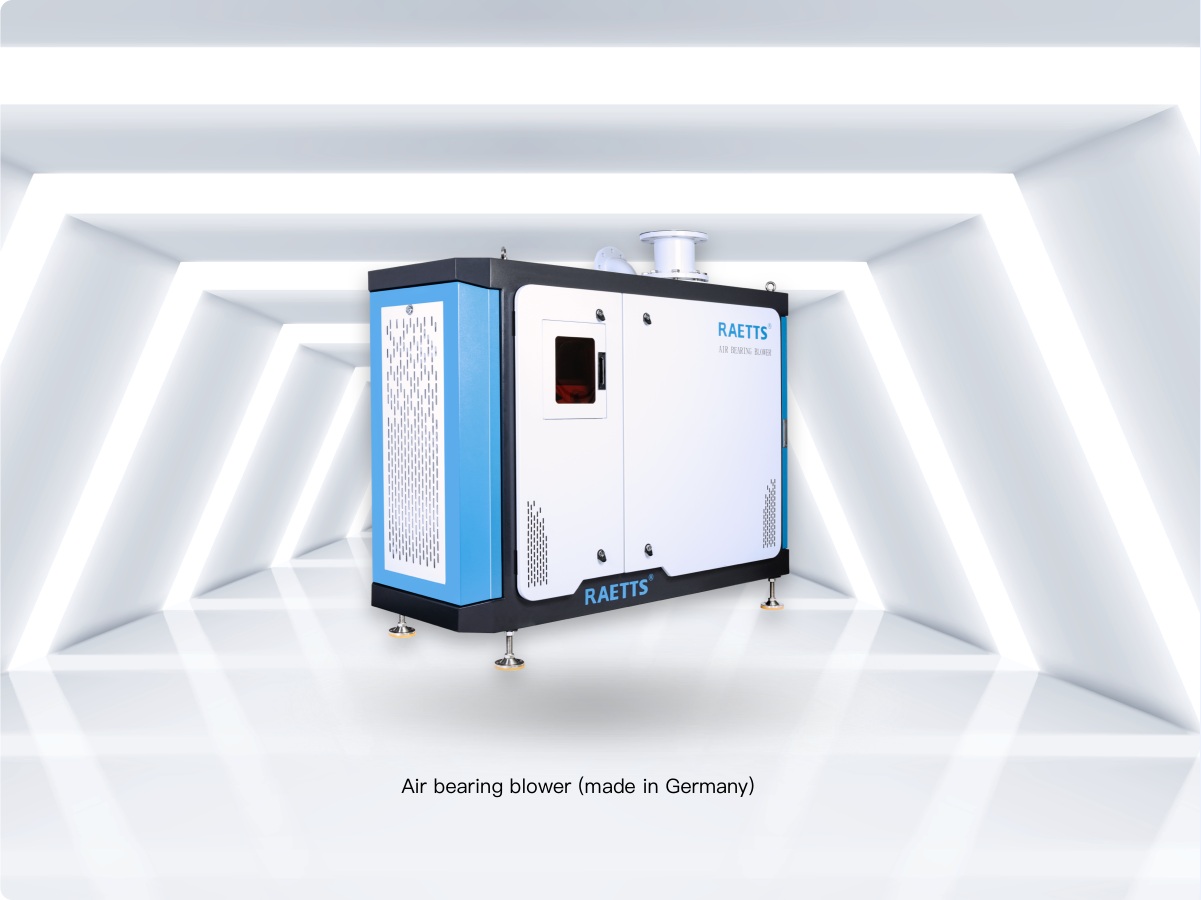

As a leading turbo blower manufacturer, RAETTS understands the importance of maintaining a clean, dust-free environment for accurate diagnostics and optimal vehicle performance. RAETTS turbo blowers are designed to provide high-efficiency airflow to assist in the automotive diagnostic process by clearing debris, cooling down engines, and maintaining clean surfaces for better precision.

In this article, we will explore how RAETTS air blower machines enhance the automotive diagnostic process, improving accuracy, efficiency, and overall service quality.

The Role of Cleanliness in Automotive Diagnostics

Automotive diagnostics often involve complex systems like engine control units (ECUs), sensors, wiring harnesses, and electrical connectors. Many of these components are sensitive to debris, dust, and moisture, which can interfere with accurate readings, diagnostics, and repairs.

Keeping diagnostic tools and the vehicle engine clean is crucial for:

- Preventing contamination: Dirt or dust particles can cause inaccurate readings and lead to improper diagnostics.

- Maintaining equipment longevity: Dust and debris can damage sensitive components, shortening the lifespan of diagnostic equipment.

- Ensuring accurate repairs: Clean tools and vehicles lead to more accurate troubleshooting and repair processes.

One effective tool for maintaining cleanliness in the automotive diagnostic process is the air blower machine, particularly high-performance RAETTS turbo blowers. These blowers provide efficient airflow to clean, cool, and maintain automotive components, ensuring a clean diagnostic environment for optimal accuracy.

How RAETTS Air Blower Machines Benefit the Automotive Diagnostic Process

1. Efficient Cooling of Engine and Electrical Systems

The automotive diagnostic process often requires examining components that operate under high temperatures, such as the engine, battery, and electrical systems. Overheating can lead to inaccurate diagnostic readings and potential damage to sensitive equipment.

RAETTS turbo blowers provide a high-volume airflow that is ideal for cooling down engines and electrical components, allowing technicians to conduct diagnostics more efficiently and safely.

How Cooling Enhances Diagnostics:

- Prevent overheating: Cooling down the engine and electrical components reduces the risk of overheating, which can lead to inaccurate sensor readings and potential damage.

- Accurate testing: Cooling components to their normal operating temperature ensures that diagnostic tests are more accurate, particularly for systems that are temperature-sensitive.

- Improved safety: Reducing heat buildup on components, especially under the hood or in the engine compartment, allows technicians to safely handle vehicles without the risk of burns or electrical malfunctions.

RAETTS Tip: Use RAETTS turbo blowers to cool down engine parts, batteries, and electrical systems before starting diagnostics or repairs to avoid overheating and ensure more reliable test results.

2. Preventing Dust Contamination in Diagnostic Equipment

Modern automotive diagnostic tools, such as OBD scanners, multimeters, and sensor testing equipment, are highly sensitive to dust and debris. If these tools or vehicle components are not clean, dust particles can interfere with readings, cause malfunctions, or even damage the equipment.

RAETTS air blower machines provide an easy and effective way to clean dust and debris from automotive diagnostic tools, connectors, and engine parts.

How Air Blowers Help with Dust Removal:

- Prevent damage to tools: Dust can damage sensitive equipment like sensors and diagnostic scanners. Using an air blower ensures that tools remain in good condition and maintain their precision.

- Clear critical connections: Dust can accumulate in electrical connectors, wiring harnesses, and sensor ports, causing poor connections or faulty readings. RAETTS turbo blowers quickly clear these areas of dust, improving diagnostic accuracy.

- Clean engine parts: RAETTS turbo blowers can be used to clear dust from hard-to-reach areas of the engine bay, especially around delicate components like the alternator, battery terminals, and intake systems.

RAETTS Tip: Use RAETTS turbo blowers in conjunction with diagnostic equipment to remove dust before testing, ensuring that all connections are clean and dust-free for accurate results.

3. Moisture Control to Prevent Short Circuits

Excess moisture is another potential issue during automotive diagnostics. Moisture accumulation on sensitive components like ECUs, wiring, and fuses can lead to short circuits and corrosion, which can affect vehicle performance and diagnostic outcomes.

RAETTS turbo blowers help reduce moisture buildup by drying out damp areas quickly and efficiently, preventing moisture-related damage during diagnostics.

How Moisture Control Enhances Diagnostics:

- Prevent corrosion: Moisture can cause corrosion on electrical connectors, wiring, and sensitive components. Using RAETTS turbo blowers ensures that moisture is removed, preventing rust and corrosion.

- Avoid short circuits: Moisture can cause short circuits in electrical systems, leading to inaccurate diagnostic readings or equipment failure. Blowing air over wet areas ensures that moisture is quickly removed, preventing electrical issues.

- Drying damp components: After rain or high humidity, using RAETTS turbo blowers to dry out electrical parts before diagnostics ensures that the vehicle’s systems perform as expected.

RAETTS Tip: Use RAETTS turbo blowers to dry off moisture from components like wiring harnesses, battery terminals, and engine parts before conducting diagnostic tests to prevent electrical malfunctions.

4. Improving Diagnostic Speed and Efficiency

In an industry where time is money, RAETTS turbo blowers can improve the speed and efficiency of the automotive diagnostic process. By quickly cleaning components, cooling systems, and ensuring moisture control, RAETTS air blowers help technicians perform diagnostics without unnecessary delays.

How Blowers Enhance Operational Efficiency:

- Speed up the cleaning process: With a powerful air blower machine, cleaning components and tools becomes a faster and more efficient task, allowing technicians to move quickly to the diagnostic phase.

- Reduce downtime: Using RAETTS turbo blowers to maintain cleanliness and cooling systems reduces downtime between diagnostic tests and repair procedures, keeping the workflow efficient.

- Boost productivity: Efficient diagnostics lead to faster repairs and service times, improving overall productivity in the shop or service center.

RAETTS Tip: Incorporate RAETTS turbo blowers into your automotive diagnostic routine to minimize downtime and increase the efficiency of your repair and service operations.

5. Improving Cleanroom Environments for Diagnostics

Some modern diagnostic equipment, especially in high-tech or electric vehicle (EV) diagnostics, may require a cleanroom environment or highly controlled areas to prevent contamination during testing. RAETTS air blower machines are ideal for maintaining a clean and controlled space by improving airflow, filtering contaminants, and reducing particle buildup.

How Cleanroom Airflow Improves Diagnostics:

- Minimize contamination: RAETTS turbo blowers can be used to ensure cleanroom environments remain free of dust and debris, ensuring accurate diagnostic readings, especially for sensitive systems like EV batteries or advanced engine control systems.

- Control airflow: Proper airflow management helps maintain ideal conditions for diagnostic testing by ensuring that dust particles do not affect the sensitive electronic systems under analysis.

RAETTS Tip: Use RAETTS turbo blowers to help maintain a cleanroom atmosphere when diagnosing advanced systems or when working with components sensitive to dust and moisture.

Conclusion: Optimize Automotive Diagnostics with RAETTS Turbo Blowers

Efficient and reliable automotive diagnostics require a clean and controlled environment, free from dust, moisture, and excessive heat. RAETTS turbo blowers play a vital role in maintaining this environment by:

- Cooling down critical components like the engine and electrical systems.

- Removing dust from tools, connectors, and engine parts to ensure accurate readings.

- Preventing moisture buildup that can cause short circuits and corrosion.

- Speeding up maintenance tasks to increase diagnostic efficiency and reduce downtime.

Whether you are diagnosing traditional combustion engines, hybrid vehicles, or the latest electric vehicles (EVs), RAETTS air blower machines are an essential tool for enhancing the accuracy, efficiency, and safety of your automotive diagnostic processes.

Contact RAETTS today to learn more about our high-performance turbo blowers and how they can optimize your automotive diagnostic and repair operations.