In the world of precision manufacturing, maintaining accuracy, cleanliness, and efficiency is paramount. Whether you are working with electronic components, machined parts, or automated assembly systems, small contaminants, heat buildup, or poor airflow can compromise product quality, increase downtime, and lead to costly defects. This is where air blower machines come into play.

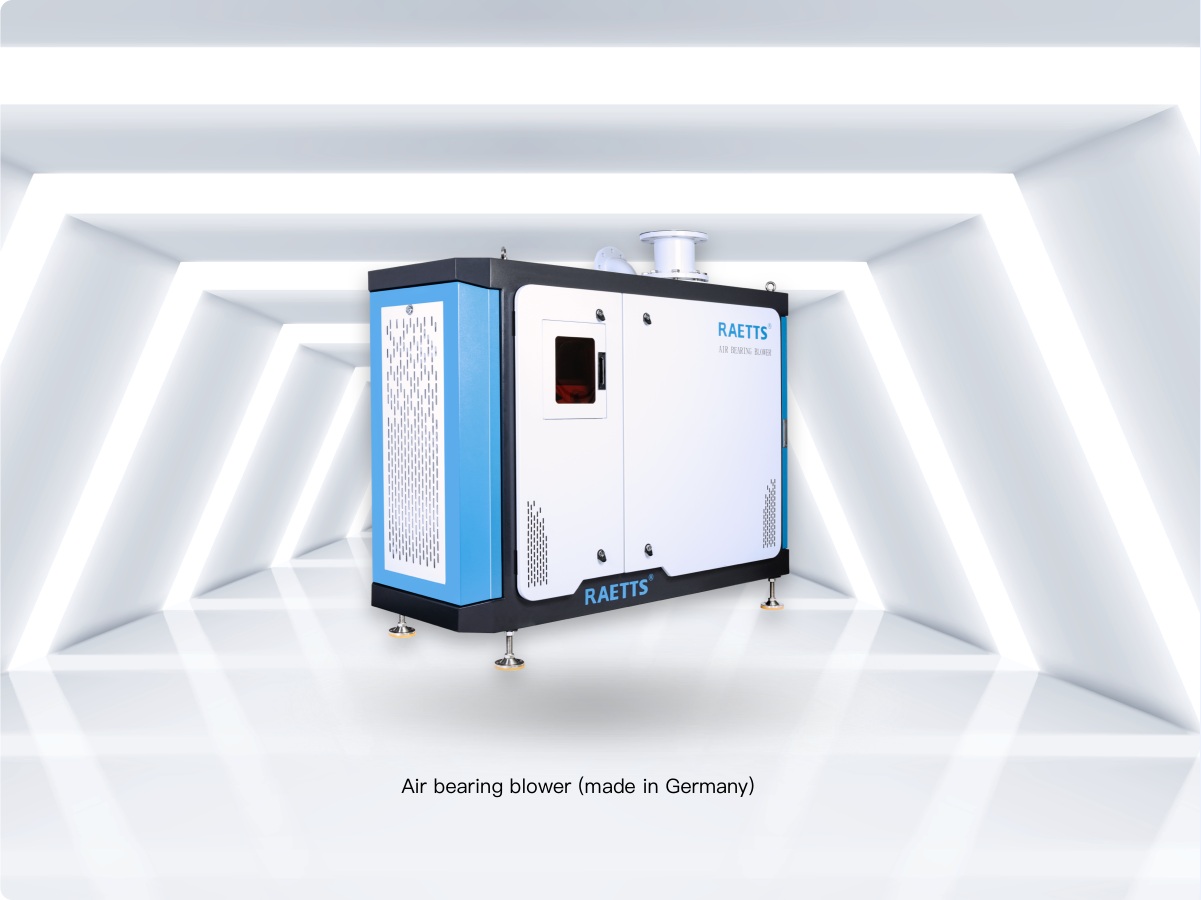

As a leading turbo blower manufacturer, RAETTS offers cutting-edge high-performance air blowers that play a critical role in ensuring clean, controlled, and precise environments for precision manufacturing. From preventing contamination to improving cooling systems and maintaining machinery, RAETTS turbo blowers are a crucial tool for any manufacturer looking to enhance operational efficiency and product quality.

In this article, we will explore how RAETTS air blower machines contribute to the precision manufacturing process and discuss the best practices for integrating these blowers into your workflow to maintain optimal productivity.

Why Cleanliness is Critical in Precision Manufacturing

Precision manufacturing relies on the creation of high-tolerance parts that must meet exact specifications. These parts can include anything from microscopically small electronic components to mechanical parts for complex machines. When dust, debris, or moisture contaminate these components, they can lead to:

- Surface imperfections: Dust and debris can cause scratches or imperfections that affect the functionality and aesthetic quality of manufactured parts.

- Inaccurate machining: Small contaminants can interfere with automated systems, causing inaccuracies in precision machining or assembly processes.

- Equipment damage: Contaminants can enter sensitive machinery, potentially causing breakdowns, malfunctions, or inefficiencies.

- Increased downtime: Cleaning up after contamination or waiting for machinery to cool down can lead to significant delays and lost productivity.

To ensure that products meet high manufacturing standards, it is essential to keep the environment clean and free from particles that could affect both the final product and the machinery used to create it. RAETTS turbo blowers provide an efficient solution to these challenges, ensuring clean, safe, and precise manufacturing environments.

How RAETTS Air Blower Machines Enhance Precision Manufacturing

1. Maintaining Clean and Dust-Free Environments

In precision manufacturing, even the smallest particle of dust can cause defects in parts or interfere with critical systems. RAETTS turbo blowers are designed to remove dust and debris from both the workspace and the components being manufactured.

Whether it’s the production floor, machinery, or individual parts, RAETTS air blowers are engineered to provide high-volume, high-velocity airflow that effectively clears away contaminants without physically touching sensitive surfaces.

Best Practices for Dust Removal with RAETTS Turbo Blowers:

- Use RAETTS air blowers to blow off debris from machined parts, robotic arms, and automated systems before assembly.

- Blow out any dust buildup on precision tools or workstations to prevent particle contamination during the manufacturing process.

- In environments with automated machinery, ensure RAETTS turbo blowers are used to maintain clean air around sensitive sensors and delicate electronics.

RAETTS Tip: For the best results, place RAETTS turbo blowers near production lines or assembly areas to continuously remove airborne particles that could compromise part quality.

2. Improving Cooling Systems for Machinery

In high-precision manufacturing, machinery such as CNC machines, milling machines, and laser cutters often operates under extreme heat conditions. Overheated machinery can lead to performance issues, reduced accuracy, or even machine failure. RAETTS turbo blowers help regulate temperatures by providing a continuous stream of cooling air, which ensures that machines remain within their optimal operating temperature range.

How Cooling Enhances Manufacturing Precision:

- Prevent overheating: RAETTS turbo blowers are ideal for cooling down hot machinery or tooling during high-speed machining or production processes, helping maintain operational efficiency.

- Ensure precision: Overheated machinery can cause dimensional inaccuracies in manufactured parts. By regulating temperature, RAETTS air blowers help ensure that parts are made to exact specifications.

- Enhance tool life: By maintaining proper cooling, RAETTS turbo blowers extend the lifespan of cutting tools, reducing the frequency of tool changes and preventing costly downtime.

RAETTS Tip: Position RAETTS turbo blowers around high-heat equipment like CNC machines or laser cutting systems to optimize cooling and maintain precision during production.

3. Enhancing Airflow for Better Ventilation

Maintaining consistent and controlled airflow is critical in precision manufacturing, especially in environments that require cleanroom standards or systems sensitive to temperature and humidity. RAETTS air blower machines provide reliable airflow for ventilation, ensuring that temperature and humidity are kept within the optimal range for precise operations.

Benefits of Improved Airflow:

- Prevent overheating: Proper airflow helps dissipate heat from machinery, preventing temperature spikes that could cause inaccuracies or machine malfunctions.

- Maintain consistent working conditions: Consistent airflow can help maintain a stable environment for both the machinery and the workers, which is especially important when operating sensitive equipment like microscopes or electronic testing devices.

- Reduce airborne contaminants: RAETTS turbo blowers can improve ventilation by circulating air and ensuring that dust or contaminants are quickly moved away from sensitive equipment and parts.

RAETTS Tip: Use RAETTS turbo blowers as part of an airflow management system to keep production areas free from contaminants while maintaining ideal environmental conditions for precise work.

4. Preventing Contamination in Cleanroom Manufacturing

Certain precision manufacturing applications, such as semiconductor production, pharmaceutical manufacturing, and medical device assembly, require cleanroom conditions. Even microscopic particles can impact the quality of the final product. RAETTS turbo blowers play a key role in maintaining cleanliness by constantly circulating air and removing airborne particles in these highly controlled environments.

How Cleanroom Airflow Enhances Manufacturing:

- Prevent contamination: By using RAETTS air blowers to maintain cleanroom conditions, you ensure that contaminants like dust, lint, and moisture do not interfere with sensitive production processes.

- Maintain air quality: RAETTS turbo blowers are ideal for ventilating cleanrooms, ensuring that the air remains free from contaminants and that products are manufactured in the highest quality environment.

RAETTS Tip: In cleanroom environments, use RAETTS air blowers as part of your air filtration system to constantly remove dust and debris from the production area, ensuring precise and accurate results.

5. Improving Overall Operational Efficiency

The consistent use of RAETTS turbo blowers across your manufacturing operations helps reduce downtime, improve product quality, and streamline production processes. By maintaining a clean, cool, and controlled environment, these blowers allow manufacturers to keep operations running smoothly and efficiently.

Benefits of Operational Efficiency:

- Reduced downtime: Regular use of RAETTS air blowers to clean machinery, tools, and parts helps reduce the need for frequent repairs, extending the life of equipment and minimizing costly downtime.

- Faster production times: With cleaner equipment and optimized cooling systems, manufacturing processes run more efficiently, leading to quicker turnaround times for products.

- Higher-quality products: By removing contaminants, managing heat, and ensuring stable air quality, RAETTS turbo blowers contribute to the production of high-quality, precision-manufactured parts.

RAETTS Tip: Schedule RAETTS turbo blower maintenance as part of your routine to keep your production lines running smoothly and ensure consistent, high-quality output.

Conclusion: Enhance Precision Manufacturing with RAETTS Turbo Blowers

In the demanding world of precision manufacturing, the importance of maintaining a clean, cool, and controlled environment cannot be overstated. RAETTS turbo blowers play a vital role in helping manufacturers:

- Keep workspaces clean by removing dust, debris, and contaminants.

- Regulate temperature to prevent overheating and ensure accurate machining.

- Optimize airflow to improve ventilation and maintain ideal conditions.

- Improve overall operational efficiency, leading to faster production times and reduced downtime.

By integrating RAETTS air blower machines into your manufacturing operations, you can enhance the quality, efficiency, and accuracy of your processes, ensuring that every product meets the highest standards of precision.

If you’re ready to optimize your precision manufacturing operations with high-performance RAETTS turbo blowers, contact us today to learn more about how we can support your manufacturing needs and help you achieve operational excellence.