The renewable energy industry is rapidly evolving, and as the demand for clean, sustainable energy sources increases, so does the need for more efficient and reliable manufacturing processes. Whether it’s the production of solar panels, wind turbines, or bioenergy equipment, maintaining high production standards and operational efficiency is paramount. One often overlooked but essential tool in this process is the air blower machine.

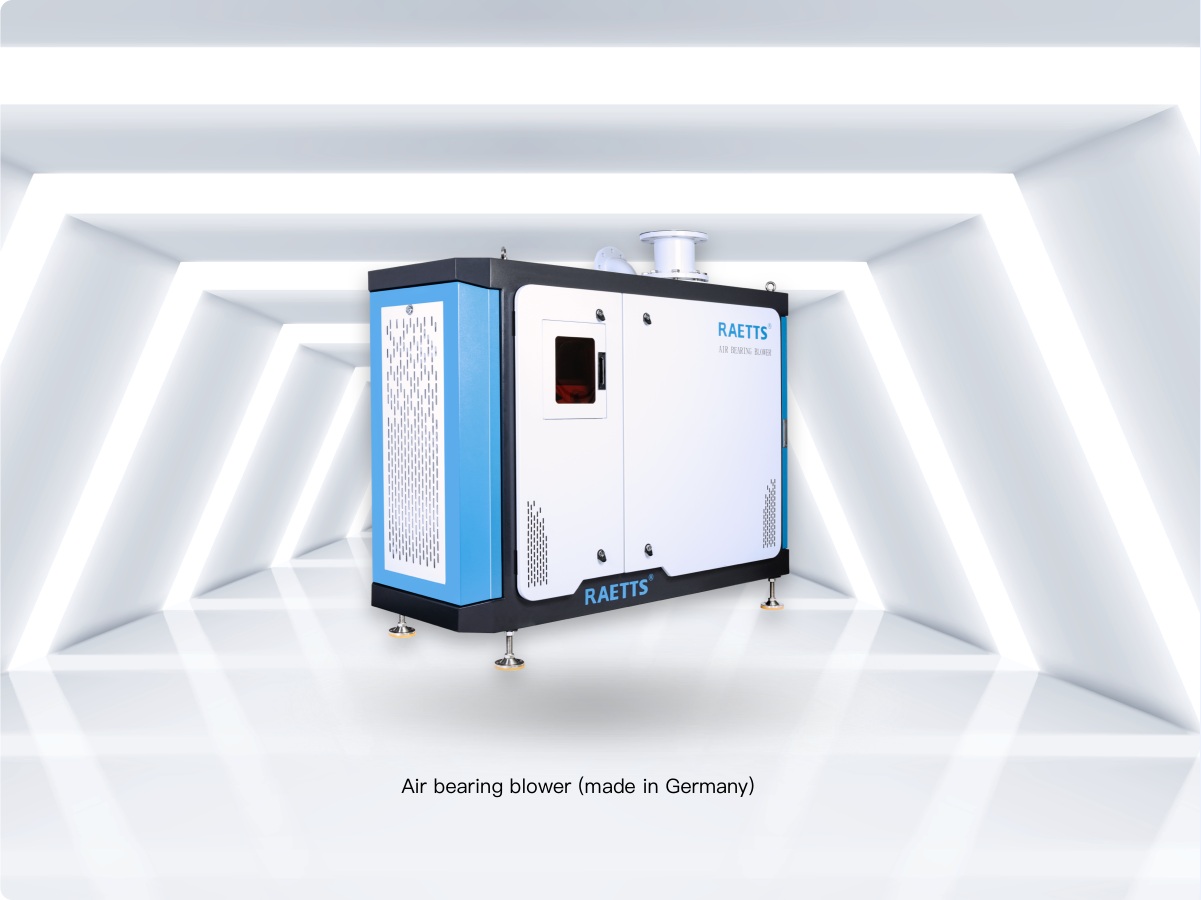

As a leading turbo blower manufacturer, RAETTS offers high-performance air blower machines that play a pivotal role in the manufacturing of renewable energy systems. These RAETTS turbo blowers help optimize the production environment, maintain equipment, and improve the quality and efficiency of renewable energy products.

In this article, we will explore how RAETTS turbo blowers are integrated into renewable energy manufacturing and the benefits they provide in improving processes and ensuring high-quality output.

The Growing Importance of Renewable Energy Manufacturing

Renewable energy is an essential part of the global effort to combat climate change and reduce reliance on fossil fuels. Manufacturing processes for renewable energy products, such as wind turbines, solar panels, hydropower components, and bioenergy systems, require stringent attention to detail and precise control of various factors, including cleanliness, cooling, and air quality.

As these industries continue to expand, manufacturers are increasingly turning to innovative technologies that can enhance productivity, lower costs, and improve the quality of their products. One such technology is the air blower machine, which is proving to be indispensable in the production of renewable energy systems.

How RAETTS Air Blower Machines Enhance Renewable Energy Manufacturing

1. Maintaining Clean and Contaminant-Free Production Areas

One of the biggest challenges in renewable energy manufacturing is ensuring that products remain clean and free from contaminants throughout the production process. For example, in the production of solar panels, even the smallest dust particles can affect the quality of the panels, leading to defects or reduced efficiency. Similarly, wind turbine blades and other large components must be kept free of debris to ensure structural integrity and performance.

RAETTS turbo blowers help create a clean, contaminant-free environment by using high-velocity air to remove dust, dirt, and other particles from machinery, work surfaces, and the products themselves. This is especially important in precision manufacturing areas where even the smallest contaminant can lead to significant defects.

How RAETTS Turbo Blowers Help:

- Use RAETTS air blowers to blow off debris from solar panels and wind turbine components during assembly.

- Clear dust and particles from manufacturing tools and workbenches to maintain a clean and controlled environment.

- Prevent contamination in critical areas of the production process, ensuring products meet quality standards.

RAETTS Tip: Set up RAETTS turbo blowers around assembly lines or quality inspection stations to keep components clean throughout production, reducing the risk of defects.

2. Optimizing Cooling Systems for Manufacturing Equipment

Manufacturing processes for renewable energy components, such as wind turbines or solar modules, often involve machinery that generates significant heat. Overheating can cause machinery to malfunction, leading to delays, reduced efficiency, and potential damage to equipment. RAETTS turbo blowers provide an effective solution for cooling machinery and maintaining optimal operating temperatures.

By utilizing RAETTS air blowers to circulate cool air and dissipate heat, manufacturers can ensure that their machinery operates within the required temperature range, preventing overheating and minimizing the risk of failure.

How Cooling Systems Benefit Manufacturing:

- RAETTS turbo blowers can be used to cool down machinery, such as CNC machines, laser cutters, or welding equipment, which are critical in the production of renewable energy systems.

- By reducing overheating, RAETTS air blowers help maintain precision during manufacturing, leading to higher-quality components.

- Efficient cooling prevents heat-related damage to solar panel assemblies or wind turbine blades, improving the overall reliability of the product.

RAETTS Tip: Place RAETTS turbo blowers around high-heat areas of the manufacturing floor to ensure efficient cooling and protect sensitive equipment from overheating.

3. Improving Airflow and Ventilation in Manufacturing Facilities

A consistent flow of clean, dry air is essential for maintaining a healthy and efficient manufacturing environment. Many renewable energy manufacturing facilities use large-scale equipment that requires optimal ventilation to ensure proper functioning. RAETTS turbo blowers can enhance airflow in production areas, improving air quality and preventing the buildup of harmful gases or dust particles.

Benefits of Improved Airflow:

- RAETTS air blowers enhance ventilation in facilities, ensuring that workspaces remain safe and comfortable for workers.

- Proper airflow is essential in the production of solar panels, as stagnant air can introduce moisture or contaminants that compromise the product quality.

- RAETTS turbo blowers help create a controlled environment by circulating air, removing airborne contaminants, and maintaining optimal working conditions.

RAETTS Tip: In facilities where solar panels or wind turbines are being produced, ensure that air is constantly circulated using RAETTS turbo blowers to maintain clean, dry conditions and prevent contamination.

4. Reducing Downtime and Improving Maintenance Efficiency

Regular maintenance of manufacturing equipment is essential to keeping production lines running smoothly. RAETTS turbo blowers can be used to clean machinery, removing dust and debris that can accumulate over time and cause components to wear out faster. By keeping machinery free of contaminants, RAETTS air blowers help extend the life of equipment and reduce maintenance-related downtime.

How Air Blowers Help Maintenance:

- RAETTS turbo blowers are effective at cleaning machinery, reducing the buildup of dust and particles that can interfere with machine operation.

- Use RAETTS air blowers to remove debris from gears, motors, and other moving parts in manufacturing machinery.

- Regular cleaning with RAETTS turbo blowers minimizes the risk of equipment failure, leading to longer operational lifespans and fewer breakdowns.

RAETTS Tip: Integrate RAETTS turbo blowers into your preventive maintenance routine to keep your production equipment in peak condition and minimize unexpected downtime.

5. Enhancing Safety in Renewable Energy Manufacturing Facilities

Manufacturing facilities for renewable energy products, especially those involved in large-scale production such as wind turbine blades or solar panel frames, often involve complex machinery and processes that require careful attention to safety standards. RAETTS turbo blowers improve safety by keeping areas clean and free from flammable dust or debris, reducing the risk of accidents in the workplace.

Safety Benefits:

- RAETTS air blowers can help reduce dust accumulation on factory floors and in machines, preventing fire hazards associated with combustible materials.

- Improved air quality contributes to a safer, more comfortable working environment, reducing respiratory issues caused by dust or particles.

- RAETTS turbo blowers also contribute to environmental safety by keeping the facility free from harmful contaminants.

RAETTS Tip: Use RAETTS air blowers in high-risk areas, such as grinding or welding stations, to remove dust and improve safety in manufacturing environments.

Conclusion: Boost Renewable Energy Manufacturing with RAETTS Turbo Blowers

As the demand for renewable energy solutions grows, manufacturers are faced with the challenge of improving productivity, efficiency, and quality in their production processes. RAETTS turbo blowers play a vital role in meeting these demands by:

- Maintaining clean, contaminant-free environments that enhance product quality.

- Optimizing cooling systems to ensure machinery operates at peak efficiency.

- Improving airflow and ventilation to create safer, healthier working conditions.

- Reducing downtime by facilitating regular maintenance and cleaning of equipment.

- Enhancing safety by preventing dust accumulation and fire hazards.

By integrating RAETTS turbo blowers into your renewable energy manufacturing processes, you can optimize operations, increase product quality, and reduce maintenance costs while ensuring that your production lines are running smoothly and efficiently.

Contact RAETTS today to learn how our high-performance air blower machines can help you take your renewable energy manufacturing to the next level. Whether you’re producing wind turbines, solar panels, or bioenergy equipment, RAETTS turbo blowers are the perfect solution for maintaining a clean, efficient, and safe manufacturing environment.