In biotechnology labs, where sterile conditions and precise environments are essential for successful research and development, maintaining a cleanroom is critical. These cleanrooms must be free from contaminants such as dust, airborne particles, and microbes, which can compromise experiments, equipment, and results. One of the most effective tools to help maintain these controlled environments is the air blower machine.

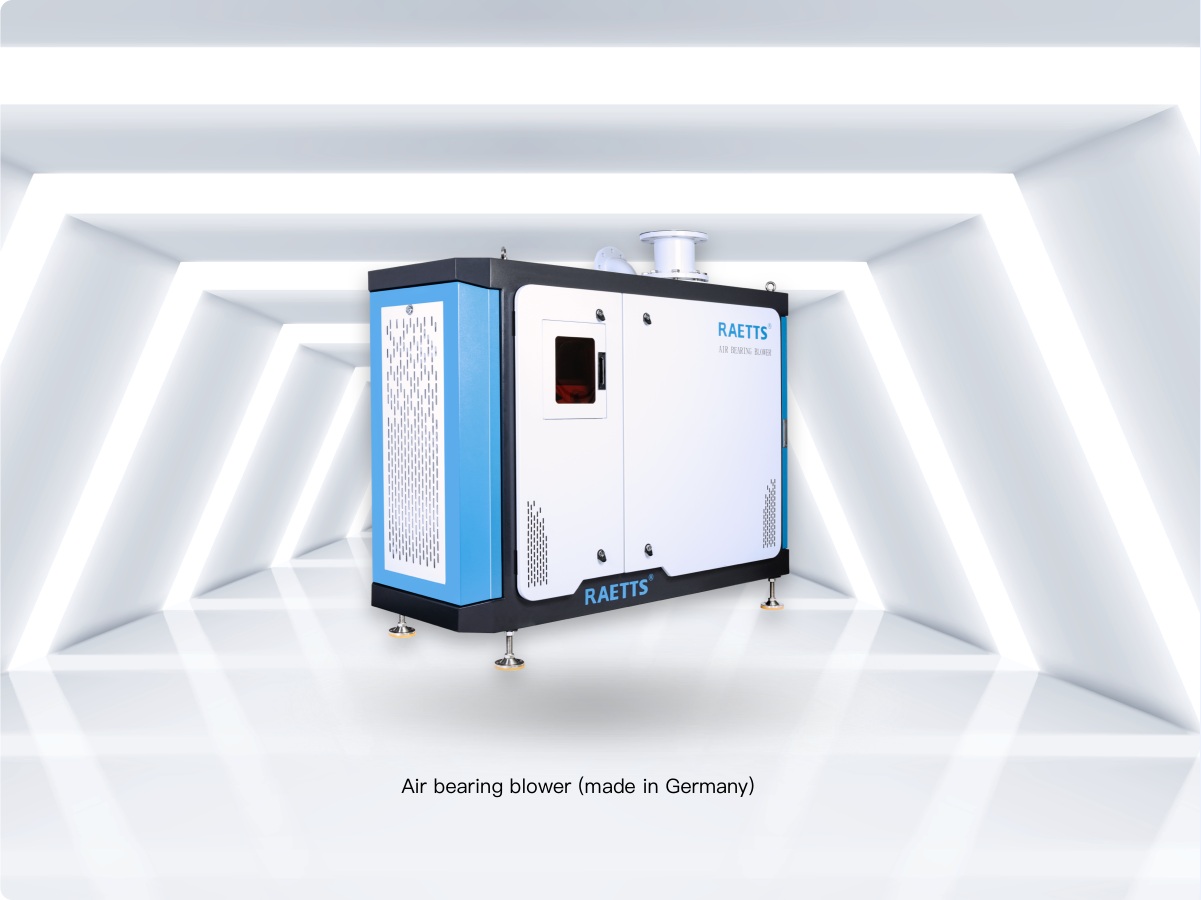

As a leading turbo blower manufacturer, RAETTS provides high-performance air blower machines that play a crucial role in maintaining cleanroom integrity in biotechnology labs. These RAETTS turbo blowers are designed to provide the clean, dry, and filtered air needed to ensure that biotechnology labs operate at the highest levels of safety, hygiene, and efficiency.

In this article, we will explore the important role that RAETTS turbo blowers play in cleanroom maintenance and how they help biotechnology labs meet stringent cleanliness and operational standards.

The Importance of Cleanroom Maintenance in Biotechnology Labs

Biotechnology labs often deal with highly sensitive and complex biological materials, such as cell cultures, DNA/RNA samples, and pharmaceutical compounds. Even a small amount of contamination can lead to faulty experiments, unreliable results, or compromised products. Therefore, maintaining a cleanroom environment that meets ISO standards is essential to minimize risks and ensure the success of lab operations.

Key Factors for Cleanroom Maintenance:

- Particle Contamination Control: Dust, particles, and microbes must be kept out of cleanrooms to protect sensitive experiments and materials.

- Air Quality Control: Cleanrooms require a continuous supply of filtered, clean, and dry air to prevent contamination.

- Humidity and Temperature Control: The air in the cleanroom must maintain specific humidity and temperature levels to ensure the stability of biological samples.

- Preventing Cross-Contamination: Lab equipment, surfaces, and personnel must be carefully monitored to avoid contamination between different areas of the lab.

The Role of RAETTS Air Blower Machines in Cleanroom Maintenance

1. Providing Clean, Filtered Air for Contaminant Control

Cleanrooms are equipped with air filtration systems to remove contaminants from the environment. However, maintaining the right air quality is a constant challenge. RAETTS turbo blowers help by providing clean, filtered air that circulates throughout the cleanroom, preventing the buildup of dust, particles, and microbes that could compromise the integrity of experiments.

By using RAETTS air blower machines, biotechnology labs can enhance their air filtration systems and ensure that cleanrooms are maintained at class 100 or class 10,000 air cleanliness standards.

Key Benefits:

- RAETTS turbo blowers are designed to provide high-velocity airflow, which helps filter out contaminants from the air.

- Ensure continuous air circulation to prevent particles from settling on surfaces and equipment.

- Support existing HVAC filtration systems by supplying clean air that meets cleanroom standards.

RAETTS Tip: Position RAETTS turbo blowers near air intakes to further enhance airflow distribution and ensure optimal air quality across the entire cleanroom space.

2. Preventing Dust and Debris Build-up on Equipment and Surfaces

In a biotechnology lab, dust and particulate matter can settle on sensitive equipment, biosafety cabinets, or laboratory surfaces, leading to contamination or equipment malfunctions. RAETTS air blowers are ideal for removing dust and debris from these surfaces without physically touching them, which could introduce additional contaminants.

The high-velocity air from RAETTS turbo blowers is perfect for blowing off dust and particles from lab benches, workstations, and equipment, ensuring they remain clean and ready for use.

Key Benefits:

- RAETTS turbo blowers are non-contact cleaning tools, reducing the risk of introducing contaminants through physical handling.

- Maintain equipment functionality by removing dust from sensors, filters, and components that could impact their performance.

- Ideal for cleaning equipment in biosafety cabinets, incubators, and microscopes, ensuring these devices operate in optimal conditions.

RAETTS Tip: Use RAETTS air blowers during routine cleaning or after any procedure that involves potentially contaminating materials to prevent buildup and ensure cleanliness.

3. Enhancing Airflow for Temperature and Humidity Control

In biotechnology labs, maintaining the right temperature and humidity is crucial for the stability and preservation of biological samples. RAETTS turbo blowers help maintain uniform air circulation across the entire cleanroom, preventing hot spots, humidity imbalances, or temperature fluctuations that could affect experiments.

By enhancing the efficiency of the HVAC system, RAETTS turbo blowers ensure that temperature and humidity levels remain consistent, which is critical for successful experiments and the quality of biological products.

Key Benefits:

- RAETTS air blowers support temperature stability and prevent heat accumulation near sensitive equipment.

- Help in distributing humidity evenly across the cleanroom, preventing moisture buildup or dryness that could damage biological samples.

- Support air distribution in temperature-sensitive areas like incubators, cold storage rooms, or bioreactors.

RAETTS Tip: Place RAETTS turbo blowers strategically around the cleanroom to optimize airflow and help maintain consistent environmental conditions.

4. Minimizing Contamination During Routine Maintenance and Cleaning

Biotechnology labs often perform routine maintenance and cleaning, including disinfection, sterilization, and decontamination procedures. During these processes, it’s crucial to avoid introducing contaminants into the lab environment.

RAETTS turbo blowers are ideal tools for drying or blowing off excess moisture from cleaned surfaces or equipment, reducing the need for manual wiping, which could introduce dust or particles. Additionally, they can be used to dry lab clothing and personnel attire before re-entering the cleanroom.

Key Benefits:

- RAETTS air blowers provide a fast, non-contact drying solution, reducing the risk of contamination from traditional cleaning methods.

- Keep lab attire and equipment dry and free of particles, ensuring they meet cleanroom standards.

- RAETTS turbo blowers help remove excess liquid from surfaces or equipment after cleaning, reducing the risk of mold, corrosion, or microbial growth.

RAETTS Tip: Use RAETTS turbo blowers to dry cleanroom apparel and lab equipment after sterilization, ensuring that items are completely free of moisture before being returned to the lab.

5. Reducing Maintenance Costs and Increasing Efficiency

Maintaining a clean and well-regulated environment in biotechnology labs can be costly. RAETTS air blowers help reduce operational costs by minimizing the need for manual cleaning and ensuring equipment longevity by keeping it free of dust and debris. The high-efficiency airflow provided by RAETTS turbo blowers also helps improve the performance of the HVAC system, reducing energy costs associated with maintaining a cleanroom environment.

Key Benefits:

- RAETTS air blowers help reduce the frequency of manual cleaning and sterilization tasks, cutting down on labor costs.

- Support the energy efficiency of the cleanroom by improving airflow and reducing strain on HVAC systems.

- Help prevent wear and tear on expensive lab equipment, reducing maintenance and replacement costs.

RAETTS Tip: Integrate RAETTS turbo blowers into your cleaning and maintenance protocols to improve overall lab efficiency and reduce operational costs.

Conclusion: Optimize Cleanroom Maintenance with RAETTS Turbo Blowers

In biotechnology labs, where precision and cleanliness are paramount, maintaining a contaminant-free and controlled environment is essential for the success of experiments and the integrity of products. RAETTS turbo blowers provide an efficient solution for cleanroom maintenance by:

- Enhancing airflow and providing filtered air to reduce contaminants in the environment.

- Preventing dust buildup on surfaces and lab equipment to ensure proper functionality and hygiene.

- Supporting temperature and humidity control to stabilize environmental conditions within the lab.

- Improving cleaning and drying processes, reducing contamination risks during routine maintenance.

By integrating RAETTS air blower machines into your cleanroom maintenance procedures, you can optimize the cleanroom environment, reduce maintenance costs, and ensure that your biotechnology lab meets the highest standards for cleanliness and operational efficiency.

Contact RAETTS today to learn more about our high-performance turbo blowers and how they can enhance the maintenance and cleanliness of your biotechnology lab’s cleanroom.