In the world of industrial applications, turbo blowers have become an essential component for processes that require efficient air movement and pressure. RAETTS, a leading turbo blower manufacturer, offers cutting-edge solutions that meet the diverse needs of various industries. This article delves into the critical aspects of turbo blower installation, ensuring that you have all the necessary information for a successful setup.

Understanding Turbo Blowers

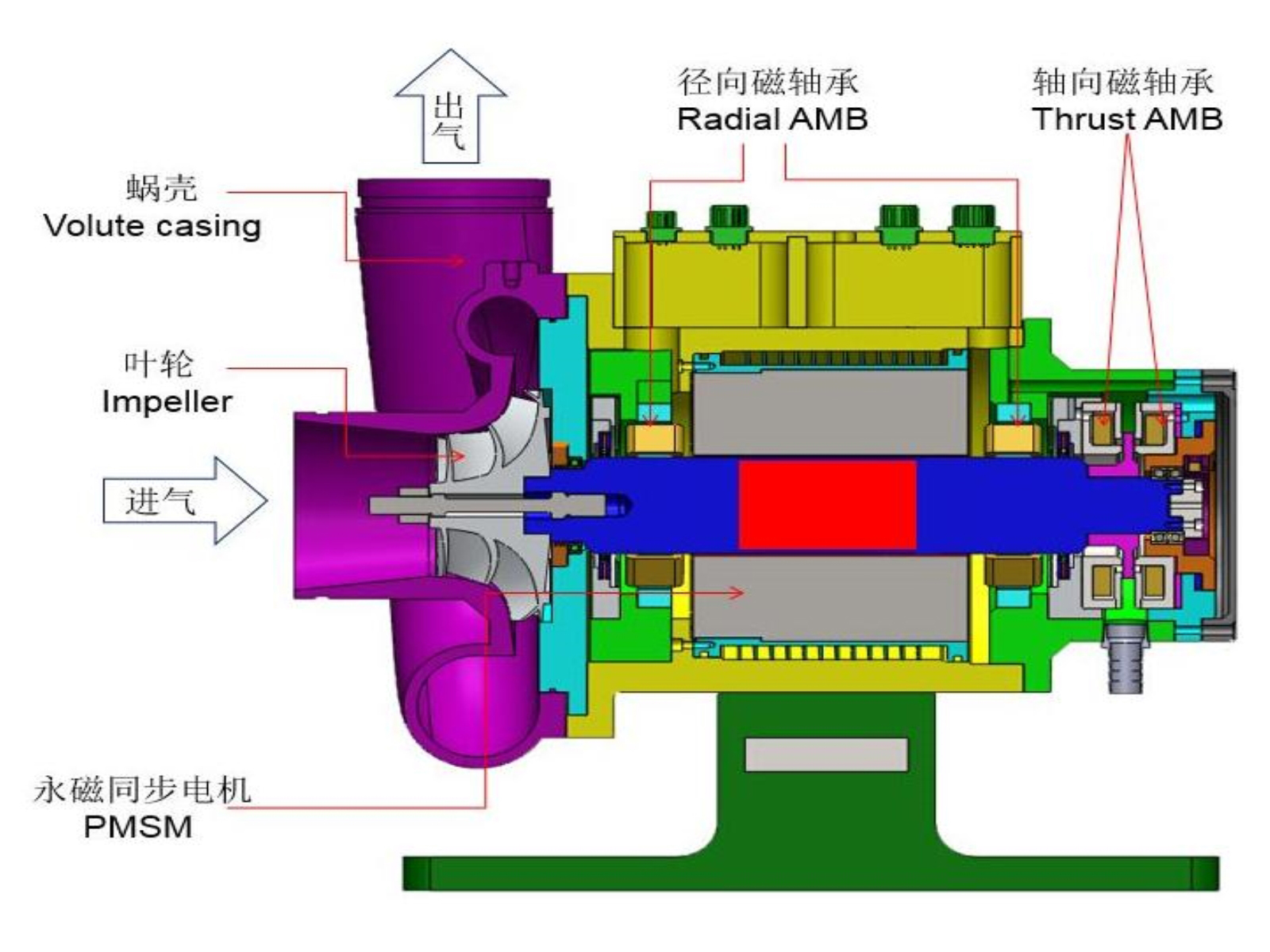

Turbo blowers are advanced machines designed to move air or gas with high efficiency and reliability. Unlike traditional blowers, turbo blowers use high-speed impellers to generate airflow, providing significant energy savings and reduced operational costs. RAETTS, as a pioneer in turbo blower technology, has developed models that cater to the specific requirements of wastewater treatment, chemical processing, power generation, and more.

Key Features of RAETTS Turbo Blowers

RAETTS turbo blowers are renowned for their innovative design and superior performance. Some of the key features include:

- High Efficiency: RAETTS turbo blowers are engineered to deliver maximum efficiency, reducing energy consumption by up to 40% compared to traditional blowers.

- Compact Design: The compact design of RAETTS turbo blowers allows for easy installation in limited spaces without compromising on performance.

- Low Noise Levels: With advanced noise-reduction technology, these blowers operate quietly, minimizing noise pollution in industrial environments.

- Durability: Built with high-quality materials, RAETTS turbo blowers are designed for long-lasting performance, even in harsh conditions.

Pre-Installation Considerations

Before embarking on the installation of a turbo blower, there are several critical factors to consider. Proper planning and assessment can significantly impact the success of the installation process.

Site Assessment and Preparation

Conducting a thorough site assessment is crucial to identify the most suitable location for the turbo blower. Consider factors such as:

- Space Availability: Ensure there is adequate space for the blower and any ancillary equipment.

- Ventilation: Proper ventilation is essential to prevent overheating and ensure optimal performance.

- Accessibility: The blower should be easily accessible for maintenance and inspections.

Power Supply Requirements

Ensure that the site has the appropriate power supply to support the turbo blower. Check voltage and frequency specifications to match the blower’s requirements. RAETTS provides detailed guidelines for power supply compatibility to prevent electrical issues.

Installation Process

Once the pre-installation considerations are addressed, the installation process can commence. Proper installation is crucial to ensure the blower operates efficiently and safely.

Mounting the Blower

Securely mount the turbo blower on a stable platform to minimize vibrations and ensure stability during operation. Use appropriate mounting hardware and follow RAETTS’s installation manual for guidance.

Piping and Ductwork

Properly connect the blower to the system’s piping and ductwork. Ensure that all connections are airtight to prevent leaks and maintain system efficiency. RAETTS provides detailed schematics to assist with the correct installation of piping and ductwork.

Electrical Connections

Connect the blower to the power supply, ensuring all electrical connections are secure and compliant with safety standards. RAETTS recommends hiring a certified electrician to handle electrical installations to avoid any potential hazards.

Post-Installation Checks

After installation, perform a series of checks to verify that the blower is functioning correctly and safely.

Operational Testing

Conduct operational tests to ensure the blower is running smoothly. Monitor parameters such as airflow, pressure, and temperature to confirm they are within specified ranges.

Safety Inspections

Perform safety inspections to identify any potential risks. Check for loose connections, unusual noises, or vibrations that may indicate installation issues.

Maintenance and Troubleshooting

Regular maintenance is essential to keep the turbo blower in optimal condition and prevent unexpected breakdowns.

Routine Maintenance

Follow RAETTS’s maintenance schedule, which includes tasks such as:

- Cleaning: Regularly clean the blower and its components to prevent dust and debris buildup.

- Lubrication: Ensure all moving parts are adequately lubricated to reduce wear and tear.

- Inspection: Periodically inspect the blower for signs of wear or damage.

Troubleshooting Common Issues

If issues arise, refer to RAETTS’s troubleshooting guide to identify and resolve common problems. Common issues include:

- Reduced Airflow: Check for blockages in the ductwork or filters.

- Excessive Noise: Inspect for loose components or worn bearings.

- Overheating: Ensure proper ventilation and check for obstructions around the blower.

Conclusion

Installing a turbo blower from RAETTS can significantly enhance the efficiency and performance of your industrial processes. By following the guidelines outlined in this article, you can ensure a successful installation that maximizes the benefits of RAETTS’s advanced turbo blower technology. Proper planning, installation, and maintenance are key to achieving optimal performance and longevity of your turbo blower system.

With RAETTS’s commitment to quality and innovation, you can be confident in the reliability and efficiency of their turbo blowers. Whether you’re upgrading an existing system or setting up a new installation, RAETTS provides the expertise and support needed for a seamless and successful setup.