In the world of industrial blowers, two technologies stand out for their efficiency and advanced engineering: Maglev Turbo Blowers and Air Bearing Blowers. Both offer unique advantages and are suitable for different applications. As a leading turbo blower manufacturer, RAETTS is committed to providing cutting-edge solutions tailored to the needs of various industries. This article delves into the specifics of each technology to help you make an informed decision.

Understanding the Basics

Before diving into the comparison, it’s essential to understand what each type of blower entails. Maglev Turbo Blowers and Air Bearing Blowers both serve the purpose of moving air or gas with high efficiency, but they achieve this through different mechanisms.

What is a Maglev Turbo Blower?

A Maglev Turbo Blower uses magnetic levitation technology to suspend the rotor in a magnetic field. This eliminates physical contact between moving parts, significantly reducing friction and wear. The absence of mechanical bearings means less maintenance and a longer lifespan. Maglev technology is known for its high efficiency and reliability, making it ideal for applications requiring continuous operation.

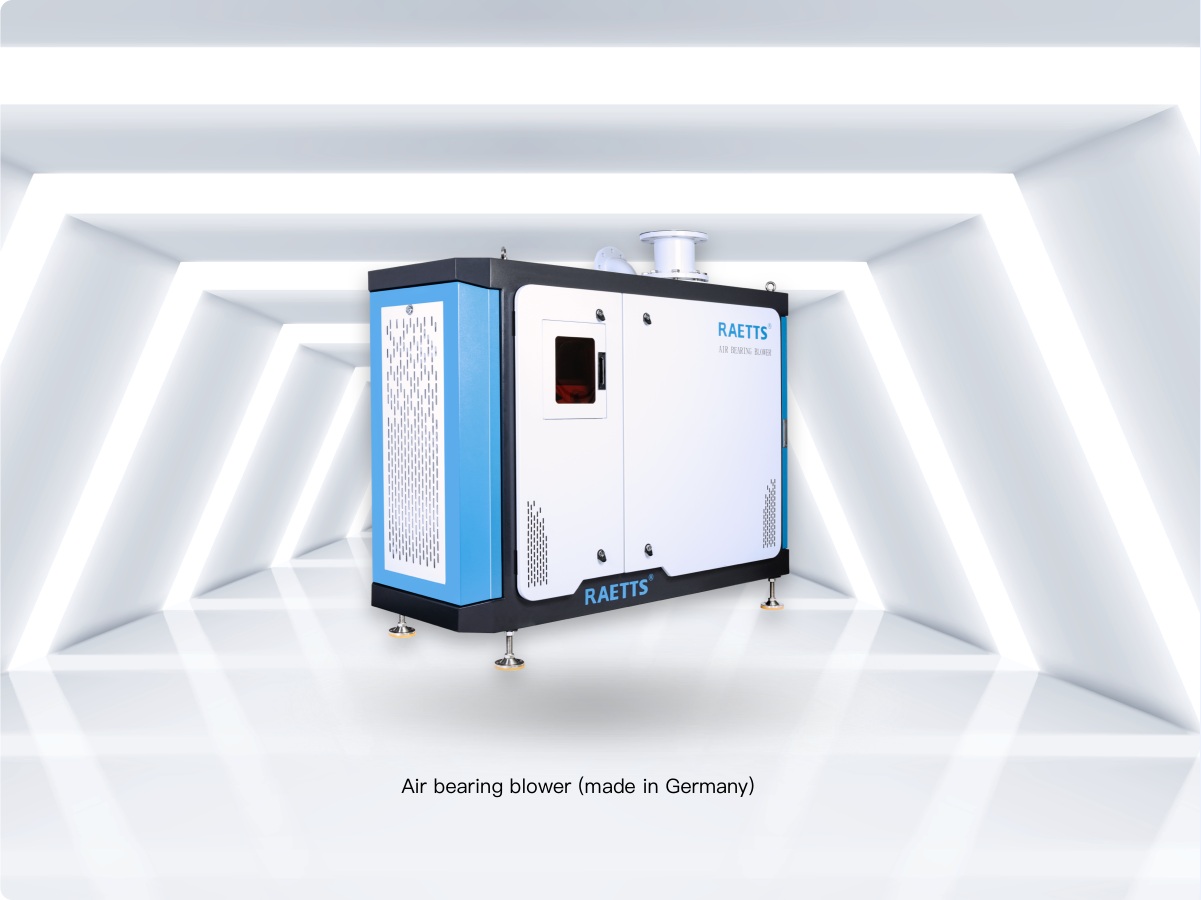

What is an Air Bearing Blower?

An Air Bearing Blower, on the other hand, uses a thin film of air to support the rotor. This air cushion minimizes friction and allows for high-speed operation. Air bearings are known for their precision and are often used in applications where minimal vibration is critical. These blowers are also maintenance-friendly due to the lack of mechanical contact.

Key Features and Benefits

Let’s explore the key features and benefits of each blower type to better understand their applications and advantages.

Maglev Turbo Blower Features

- No Mechanical Contact: The absence of physical contact reduces wear and tear, ensuring a longer operational life.

- High Efficiency: Magnetic levitation reduces energy loss, making these blowers highly efficient.

- Low Maintenance: With no mechanical bearings to replace, maintenance costs and downtime are minimized.

- Quiet Operation: The lack of friction results in quieter operation, which is beneficial in noise-sensitive environments.

Air Bearing Blower Features

- Precision and Stability: The air cushion provides excellent stability and precision, ideal for sensitive applications.

- High-Speed Operation: Capable of operating at high speeds due to minimal friction.

- Environmentally Friendly: Requires no lubrication, reducing environmental impact.

- Cost-Effective: Lower initial cost compared to maglev blowers, making them accessible for smaller operations.

Comparative Analysis

When deciding between a Maglev Turbo Blower and an Air Bearing Blower, several factors should be considered, including efficiency, cost, maintenance, and application requirements.

Efficiency

Maglev Turbo Blowers typically offer higher efficiency due to the complete elimination of mechanical friction. This makes them suitable for applications where energy savings are a priority. Air Bearing Blowers are also efficient but may not match the energy savings of maglev technology due to the slight friction from the air cushion.

Cost

In terms of initial investment, Air Bearing Blowers tend to be more cost-effective. They provide a good balance of performance and cost, making them ideal for operations with budget constraints. Maglev Turbo Blowers, while more expensive initially, often provide cost savings over time due to lower energy consumption and maintenance costs.

Maintenance

Both types of blowers require minimal maintenance compared to traditional mechanical blowers. However, Maglev Turbo Blowers have the edge due to the complete absence of mechanical bearings, which eliminates the need for frequent replacements and inspections. Air Bearing Blowers, while also low-maintenance, may require occasional checks to ensure the air cushion remains intact.

Application Requirements

The choice between a Maglev Turbo Blower and an Air Bearing Blower largely depends on the specific requirements of your application. For industries where precision and stability are paramount, such as semiconductor manufacturing or medical equipment, Air Bearing Blowers are often the preferred choice. Conversely, for applications demanding continuous operation and high efficiency, such as wastewater treatment or large-scale HVAC systems, Maglev Turbo Blowers are more suitable.

RAETTS: Your Trusted Turbo Blower Manufacturer

RAETTS is a pioneer in the development and manufacturing of high-performance turbo blowers. With a focus on innovation and quality, we provide solutions that meet the diverse needs of our clients. Our Maglev Turbo Blowers and Air Bearing Blowers are engineered to deliver exceptional performance, reliability, and efficiency.

Our commitment to customer satisfaction is reflected in our comprehensive after-sales support and service. We understand that each industry has unique challenges, and we work closely with our clients to provide tailored solutions that enhance their operations.

Conclusion

Choosing between a Maglev Turbo Blower and an Air Bearing Blower depends on various factors, including efficiency, cost, maintenance, and specific application needs. Both technologies offer distinct advantages, and the right choice will depend on your operational requirements and budget.

RAETTS is dedicated to helping you make the best choice for your industry. Our team of experts is available to provide guidance and support, ensuring you select the blower that aligns with your goals and enhances your operations.

For more information on our products and services, please visit our website or contact us directly. Let RAETTS be your partner in achieving optimal performance and efficiency in your industrial applications.