Material handling systems are the backbone of many industrial processes, providing the infrastructure needed to move raw materials, parts, and finished products efficiently and safely throughout a manufacturing or warehouse environment. From conveyors and lifts to automated systems and robotic arms, material handling plays a key role in improving productivity, reducing downtime, and ensuring that materials are delivered to the right place at the right time. However, for these systems to function optimally, they require a consistent, high-pressure air supply for lifting, transporting, and positioning materials.

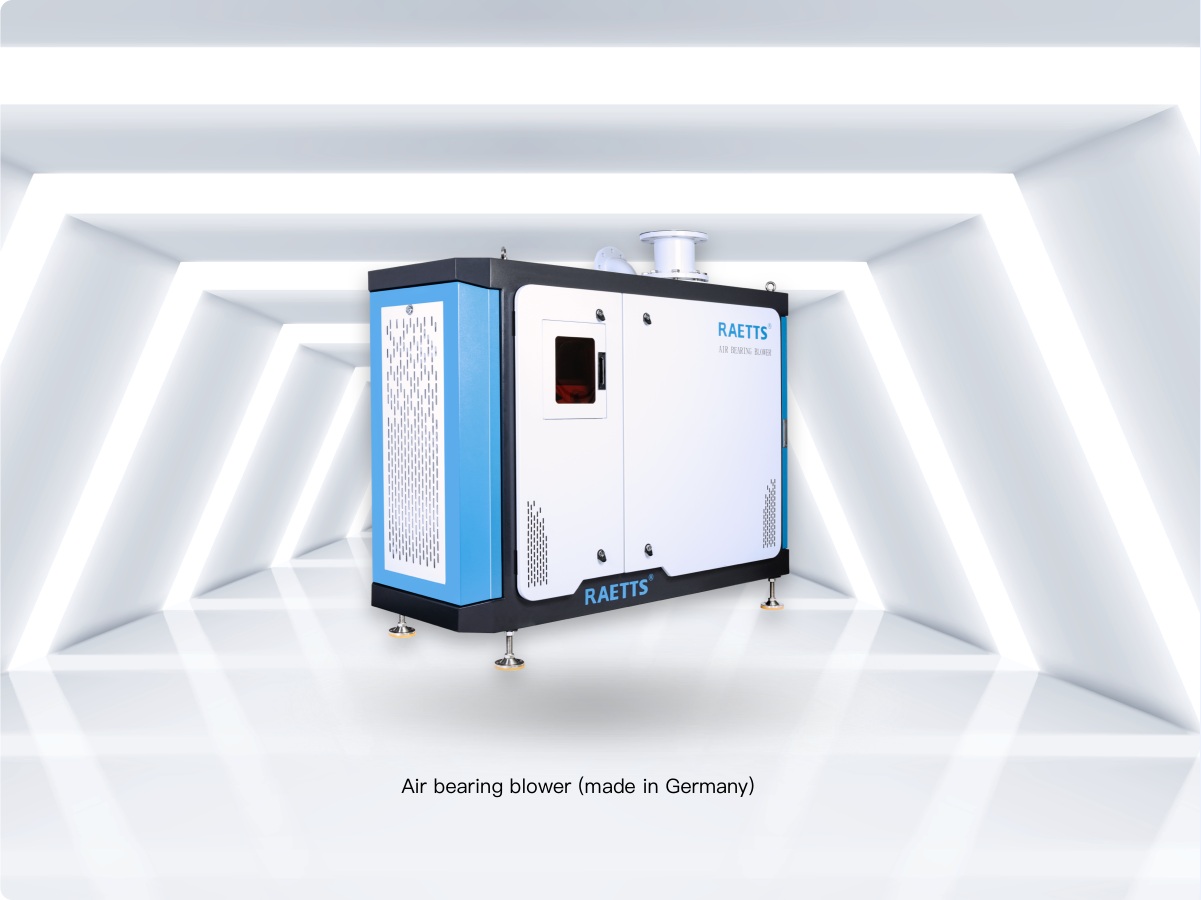

RAETTS, a leading manufacturer of turbo blowers, provides advanced solutions for material handling systems. RAETTS turbo blowers offer high-efficiency, high-pressure air that can significantly improve the performance of material handling operations, from conveyor systems to pneumatic transport solutions. In this article, we explore how RAETTS turbo blowers enhance material handling systems by improving air supply, energy efficiency, system reliability, and overall productivity.

1. Introduction to Turbo Blowers in Material Handling Systems

Material handling systems are used across a variety of industries, including manufacturing, warehousing, logistics, and distribution. These systems rely on mechanical, electrical, and pneumatic technologies to move materials through production lines or storage areas. Among the most important technologies are pneumatic conveyors, air-lift systems, and vacuum-driven devices, all of which require consistent and reliable air pressure to function.

RAETTS turbo blowers are designed to provide high-flow, high-pressure air that is essential for the smooth operation of these systems. Unlike traditional rotary blowers, which use oil-lubricated components, RAETTS turbo blowers use oil-free, dry compression technology. This ensures a cleaner, more reliable air supply, which is particularly important in industries where contamination can be costly or dangerous. The high-efficiency design of RAETTS turbo blowers helps reduce energy consumption, improve performance, and support the long-term reliability of material handling systems.

2. The Role of RAETTS Turbo Blowers in Material Handling Systems

RAETTS turbo blowers are integral to several key functions in material handling, providing the necessary airflow and air pressure to transport materials efficiently, reduce system wear, and increase operational throughput. Here are several ways in which RAETTS turbo blowers contribute to the success of material handling systems:

- Pneumatic Conveying Systems: Pneumatic conveying is widely used for moving bulk materials such as powders, pellets, and granules. These systems rely on high-pressure air to carry materials through pipes and tubes to various destinations within a facility. RAETTS turbo blowers provide the continuous, high-flow air needed to efficiently transport materials over long distances and through complex pipeline systems. With their high-pressure output, turbo blowers are able to maintain the velocity of the material flow, ensuring that materials are moved smoothly without clogging, blockages, or excessive wear on the system.

- Vacuum Systems for Material Handling: Vacuum systems are often used for lifting and positioning materials in automated material handling systems. For example, in pick-and-place systems, vacuum suction is used to lift delicate or small items for transport or packaging. RAETTS turbo blowers provide the necessary vacuum pressure to these systems, ensuring consistent lifting power and stability. With the right suction pressure, materials can be moved with precision, without risk of damage or slippage. Additionally, RAETTS turbo blowers are capable of providing continuous suction, which is essential for maintaining consistent material handling in fast-paced production lines.

- Air-Lift Systems for Heavy Materials: Some material handling systems use air-lift techniques to transport large or heavy materials, such as containers, crates, or heavy pallets. RAETTS turbo blowers generate the high-volume air necessary to lift and move these heavy loads in air-supported tracks or conveyors. The strong, consistent airflow provided by turbo blowers allows for greater load capacities, which can significantly reduce the need for manual handling, increase safety, and speed up the material transfer process.

- Sorting and Positioning Systems: In many automated warehouses or sorting systems, materials need to be directed to specific locations based on predefined criteria. Pneumatically controlled diverting systems use controlled airflow to push materials onto different conveyor lines or to change their direction. RAETTS turbo blowers are crucial to providing the precise air pressure required to move materials accurately and efficiently, ensuring smooth transitions between sorting stations. The high-speed air generated by turbo blowers enhances the responsiveness and flexibility of sorting systems, allowing for real-time adjustments in material flow.

- Air-Driven Actuators for Automated Systems: Many modern material handling systems rely on air-driven actuators, such as pneumatic cylinders or valves, to automate the handling of materials. These actuators perform tasks such as pushing, pulling, lifting, or clamping materials at various stages in the production process. RAETTS turbo blowers supply the compressed air required for these actuators to function. Their reliable air supply ensures that actuators operate smoothly, reducing the risk of failure or delay, and improving the overall efficiency of automated material handling systems.

- Reducing Contamination and Improving Cleanliness: In industries such as food processing, pharmaceuticals, and electronics manufacturing, contamination control is a critical concern. The use of oil-free turbo blowers from RAETTS ensures that the air supplied to material handling systems is free from oil or other contaminants, which could otherwise compromise product quality. This is particularly important in environments where high cleanliness standards must be maintained. RAETTS blowers also reduce the need for regular maintenance associated with oil-lubricated blowers, helping to reduce downtime and ensure that air quality remains pristine.

3. How Turbo Blowers Enhance Efficiency in Material Handling Systems

3.1. Improved Energy Efficiency

Energy consumption is a significant factor in the cost structure of material handling systems, especially in large-scale operations where blowers run continuously for long periods. RAETTS turbo blowers are engineered for energy efficiency, using advanced technology to minimize power consumption without sacrificing performance. The design of these blowers allows them to operate at variable speeds, adjusting airflow as needed based on the specific requirements of the material handling system.

By optimizing the blower’s speed and output, RAETTS turbo blowers ensure that energy is only used when necessary, reducing electricity consumption and lowering operational costs. This is particularly beneficial in systems that experience fluctuating demand or operate in cycles, as the blowers can scale their output in response to real-time needs.

3.2. Enhanced System Reliability

Material handling systems are often a critical part of the production process, meaning any downtime or failure can have significant consequences on output and efficiency. RAETTS turbo blowers are designed to deliver reliable, consistent performance under demanding conditions. Their oil-free, dry compression technology eliminates the risks associated with oil contamination and reduces the maintenance requirements typically associated with traditional blowers.

RAETTS turbo blowers also feature advanced monitoring systems that track performance in real-time, identifying potential issues before they lead to failure. This proactive approach helps to maintain continuous operation and avoid unplanned downtime, which can be costly in high-output environments.

3.3. Increased Throughput and Productivity

Turbo blowers from RAETTS are capable of delivering high-pressure air at consistent flow rates, which enables faster material handling. By providing the right amount of airflow for pneumatic systems, RAETTS blowers enable materials to be moved more quickly and efficiently, reducing the time spent on material transport and handling. This improved throughput leads to increased overall productivity, allowing manufacturing or distribution operations to process more materials in less time.

Whether used in automated assembly lines, warehouse sorting systems, or bulk material transport systems, the high-efficiency performance of RAETTS turbo blowers helps optimize material handling processes and minimize bottlenecks.

3.4. Enhanced System Flexibility and Scalability

RAETTS turbo blowers offer flexibility in a variety of material handling applications. Their modular design allows them to be easily integrated into existing systems or scaled up for larger operations. This is especially beneficial for businesses that are expanding or upgrading their material handling capabilities. The ability to add or remove turbo blowers as needed ensures that the system can adapt to changing production requirements, helping businesses maintain optimal material handling efficiency.

Additionally, RAETTS turbo blowers can be integrated with a range of pneumatic components, including valves, actuators, and control systems, which enhances the overall versatility of the material handling setup.

3.5. Noise Reduction and Worker Comfort

In many industrial settings, noise generated by machinery such as blowers can create a challenging work environment. Traditional blowers can be loud and disruptive, affecting worker comfort and potentially violating noise regulations. RAETTS turbo blowers are designed to operate with reduced noise levels compared to conventional rotary blowers. Their quieter operation helps create a more comfortable work environment for employees and ensures compliance with occupational health and safety regulations regarding noise exposure.

3.6. Sustainable and Eco-Friendly Operations

In today’s industrial landscape, sustainability is a key consideration for manufacturers and warehouse operators. RAETTS turbo blowers contribute to environmentally friendly operations by reducing energy consumption, minimizing maintenance, and eliminating the need for oil lubrication. This oil-free technology not only reduces the environmental impact associated with oil disposal but also contributes to cleaner, greener operations overall.

The energy-efficient design of RAETTS turbo blowers aligns with sustainability goals by helping businesses reduce their carbon footprint while maintaining high performance and operational efficiency.

4. Applications of Turbo Blowers in Material Handling Systems

4.1. Pneumatic Conveying of Bulk Materials

RAETTS turbo blowers are ideal for efficiently moving powders, granules, and other bulk materials through pipelines, reducing the risk of blockages and maintaining consistent material flow.

4.2. Vacuum Lifting and Transport

Turbo blowers enable the safe and efficient lifting and handling of delicate or heavy materials using vacuum-powered systems.

4.3. Air-Supported Conveyors

RAETTS turbo blowers provide the high-pressure air necessary for air-supported conveyors, improving material movement without friction or wear.

4.4. Automated Sorting and Diverting Systems

Turbo blowers are used in automated sorting systems to control material flow and direct items to specific conveyor lines or storage locations.

4.5. Air-Driven Actuators

RAETTS turbo blowers supply the compressed air required for pneumatic actuators in automated material handling, enhancing system automation and efficiency.