Laboratories, whether they are in academic research institutions, pharmaceutical companies, or hospitals, require carefully controlled environments to ensure both safety and precision. Maintaining the correct balance of air quality, temperature, humidity, and pressure is crucial to ensure accurate experimental results, protect the health of laboratory personnel, and safeguard sensitive materials. Among the critical components of laboratory ventilation systems, turbo blowers play a significant role in optimizing airflow and ensuring compliance with stringent environmental standards. This article examines the importance of turbo blowers in laboratory ventilation systems, with a focus on RAETTS, a leading manufacturer of turbo blowers, and how their technology contributes to the efficiency and safety of laboratory environments.

1. Introduction to Turbo Blowers and Their Role in Laboratory Ventilation

Turbo blowers, also referred to as centrifugal blowers, are high-efficiency fans that generate airflow by accelerating air through centrifugal force. These blowers are widely used in ventilation systems to maintain proper air circulation and control air quality, which is essential in laboratories where a range of sensitive experiments and processes occur. The need for consistent and reliable airflow in laboratories is driven by several factors, including the potential presence of hazardous substances, the requirement for sterile conditions, and the necessity to maintain controlled environments for sensitive experiments.

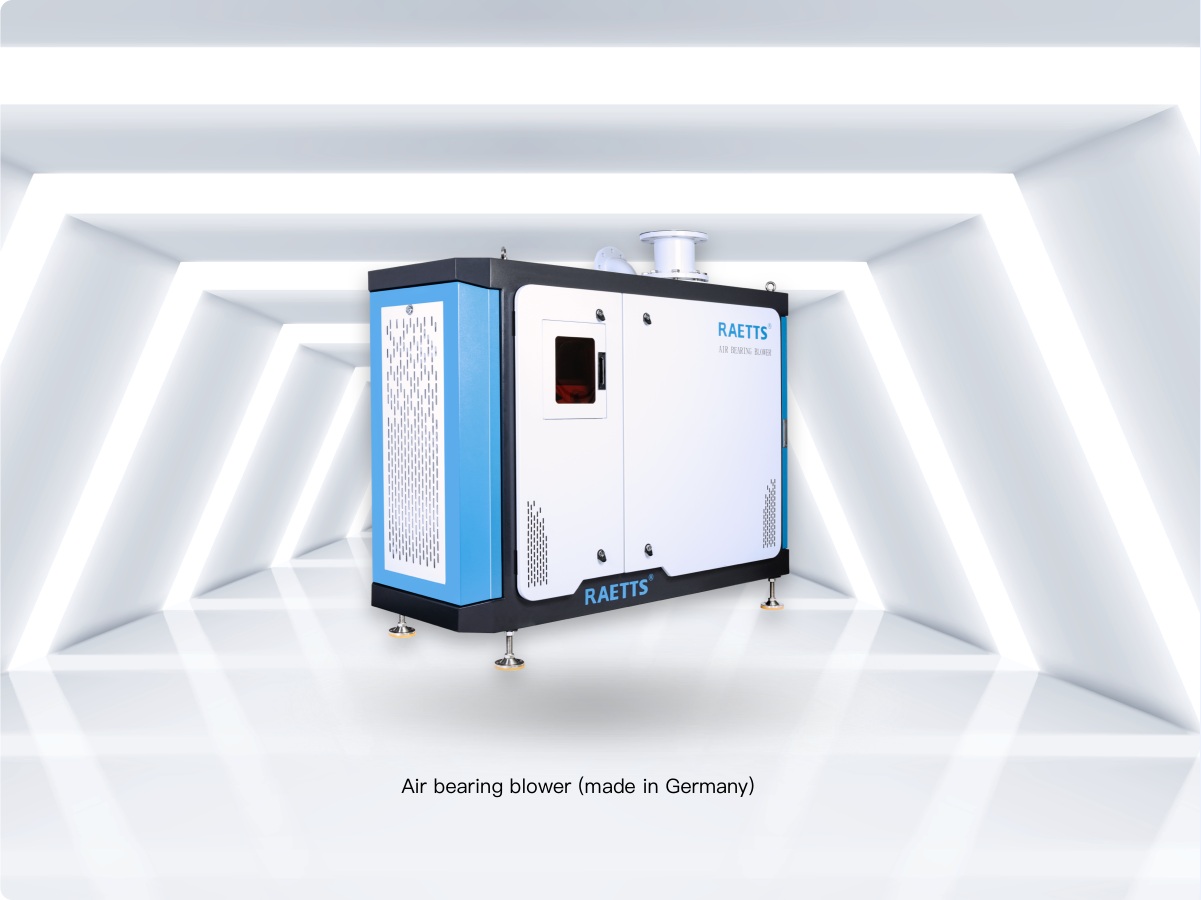

RAETTS, a prominent manufacturer of turbo blowers, provides high-performance solutions designed to meet the specific needs of laboratory ventilation systems. RAETTS turbo blowers offer several key features, including energy efficiency, reliability, quiet operation, and customizability, making them an ideal choice for laboratories of all sizes and types.

2. The Role of RAETTS in Laboratory Ventilation Systems

RAETTS has been a trusted supplier of turbo blowers for a variety of industries, including laboratories, where precise environmental control is essential. RAETTS turbo blowers are designed with the following features that make them particularly well-suited for laboratory applications:

- Energy Efficiency: Laboratories often operate 24/7, consuming large amounts of energy for ventilation and climate control. RAETTS turbo blowers are designed with high energy efficiency in mind, reducing the overall energy consumption of laboratory HVAC (heating, ventilation, and air conditioning) systems while maintaining optimal airflow performance.

- Low Noise and Vibration: Laboratories require quiet and stable environments for accurate experiments and research. RAETTS turbo blowers operate with minimal noise and vibration, ensuring that the laboratory atmosphere remains undisturbed. This feature is especially critical in research environments where sensitive equipment or precise measurements are involved.

- Durability and Reliability: Given that laboratories require continuous operation of their ventilation systems, RAETTS turbo blowers are built for reliability. With advanced engineering and durable materials, RAETTS blowers offer long-term performance with minimal maintenance, ensuring that laboratory ventilation systems can operate smoothly without frequent disruptions.

- Customizable Solutions: RAETTS understands that laboratories come with diverse requirements based on their size, complexity, and specific needs. RAETTS turbo blowers can be tailored to meet these needs, offering customization in terms of airflow, pressure, and integration with existing HVAC systems. This flexibility ensures that laboratories can maintain optimal conditions for their particular applications.

- Compact Design: Laboratory space is often limited, especially in smaller research labs or institutions. RAETTS turbo blowers are designed to be compact and space-efficient, providing powerful airflow in a compact form factor. This makes them ideal for integration into laboratory HVAC systems without occupying excessive space.

3. How Turbo Blowers Enhance Laboratory Ventilation and Safety

3.1. Airflow Control and Pressure Management

One of the primary functions of turbo blowers in laboratory ventilation systems is to manage airflow and maintain proper pressure differentials. Laboratories often require specific airflow patterns to ensure the safe handling of chemicals, biological agents, and other potentially hazardous materials. For example, laboratories working with toxic or volatile substances need to ensure that air is drawn away from personnel and hazardous materials are contained within the work area.

Turbo blowers are used to create a continuous flow of air that helps direct potentially harmful contaminants out of the laboratory while ensuring that clean air enters the space. In critical areas such as fume hoods, clean rooms, and biosafety cabinets, RAETTS turbo blowers help regulate airflow to prevent the spread of contaminants, ensuring the safety of laboratory staff and protecting sensitive experiments.

Additionally, maintaining the right air pressure within the laboratory is crucial. In some laboratory settings, negative pressure is required to ensure that hazardous substances do not escape into the surrounding environment. Conversely, positive pressure may be necessary in sterile or cleanroom environments to prevent contamination from external sources. RAETTS turbo blowers help manage these pressure differentials, ensuring that the laboratory environment remains safe and controlled.

3.2. Air Filtration and Containment

Laboratories handling hazardous materials, chemicals, or biological agents rely on advanced air filtration systems to remove particulates, vapors, and pathogens from the air. Turbo blowers play an essential role in supporting these filtration systems by providing the necessary airflow to push air through HEPA (High-Efficiency Particulate Air) filters, activated carbon filters, or other specialized filtration systems.

RAETTS turbo blowers are engineered to work in tandem with these filtration systems, ensuring that laboratory air is thoroughly filtered before being recirculated or expelled. By maintaining a constant, regulated airflow, these blowers ensure that hazardous substances are contained and that the air quality within the laboratory remains safe for researchers and staff.

In laboratories that work with biological or chemical agents, fume hoods and biosafety cabinets are critical pieces of equipment that help contain and control airborne contaminants. Turbo blowers are often integrated into these systems to ensure that the air is effectively drawn through the hood or cabinet, filtered, and safely vented to the outside, minimizing exposure to harmful substances.

3.3. Temperature and Humidity Control

In many laboratory settings, maintaining specific temperature and humidity levels is crucial for the accuracy of experiments, as well as the stability of sensitive materials. Fluctuations in temperature and humidity can compromise both the integrity of experiments and the health of laboratory staff. Turbo blowers support the HVAC systems that regulate temperature and humidity by providing consistent airflow that aids in the distribution of conditioned air.

RAETTS turbo blowers can be integrated into the laboratory’s climate control systems to support optimal conditions. For example, in laboratories that require precise temperature control, turbo blowers help distribute cooled or heated air evenly, ensuring that all areas of the lab maintain the desired temperature. Similarly, by promoting proper airflow, turbo blowers assist in maintaining the appropriate humidity levels, which is especially important in laboratories that handle biological or chemical materials sensitive to moisture changes.

3.4. Efficiency and Sustainability

Laboratories can be energy-intensive environments due to the constant need for ventilation, climate control, and specialized equipment. RAETTS turbo blowers are designed with energy efficiency in mind, offering a sustainable solution that reduces operating costs while maintaining the required performance. By using advanced technologies such as variable frequency drives (VFDs), RAETTS turbo blowers optimize energy use by adjusting the blower speed based on real-time demand, reducing waste and lowering electricity consumption.

RAETTS also focuses on the durability and long lifespan of their turbo blowers, which reduces the frequency of maintenance and replacements, further minimizing the environmental impact and the total cost of ownership. This contributes to a more sustainable laboratory operation in the long term.

4. Applications of Turbo Blowers in Laboratory Environments

4.1. Fume Hoods and Exhaust Systems

Fume hoods are essential for laboratories that work with volatile chemicals or hazardous materials. Turbo blowers support the exhaust systems in fume hoods by providing the necessary airflow to capture and remove harmful fumes, vapors, and gases. By ensuring a continuous flow of air, RAETTS turbo blowers help contain hazardous substances within the hood, preventing exposure to laboratory staff and ensuring compliance with safety standards.

4.2. Cleanrooms and Sterile Laboratories

Cleanrooms, used in industries like pharmaceuticals, biotechnology, and microelectronics, require stringent air quality and cleanliness standards. RAETTS turbo blowers play a vital role in maintaining the positive pressure needed in these environments, ensuring that contaminants from outside do not enter. These blowers are integrated with HEPA filtration systems to ensure that the air within the cleanroom remains free of particulates and microorganisms.

4.3. Biosafety Laboratories

Biosafety laboratories, particularly those working with hazardous biological agents, require constant air circulation to ensure the containment of pathogens and prevent cross-contamination. Turbo blowers are integrated into the ventilation systems of biosafety laboratories to provide controlled, regulated airflow and maintain the necessary negative or positive pressure in different areas of the lab.

4.4. Pharmaceutical Laboratories

Pharmaceutical laboratories require tightly controlled environments for the development and production of drugs. Turbo blowers are used to ensure that the airflow is consistent and that contaminants are removed from the air. These blowers help maintain sterile conditions in both laboratory spaces and production areas, where the slightest variation in air quality could compromise the integrity of experiments or products.