Optimizing the industrial structure and energy structure, and upgrading technology and equipment have become an inevitable choice for paper mills to reduce carbon dioxide emissions.

The blower is the key equipment in sewage treatment, which can continuously transport a large amount of air to sewage.

Blower operation requires a lot of electricity. How to ensure trouble-free and stable operation of equipment while reducing energy consumption and carbon dioxide emissions is a difficult problem for many enterprises.

Paper mills using traditional blowers, usually face the following problems:

Traditional root blowers and multistage centrifugal blowers are inefficient and noisy, need lubricating oil, have high fault rates, and are expensive to maintain.

Some paper mills try to use the air-bearing blower, which is one of the most advanced blowers in the world and has great advantages compared with traditional blowers. However, some paper mills face frequent start-stop conditions, and some air suspension centrifugal turbo blowers are prone to failure after frequent start-stop operation for some time, and customers will face the trouble of high maintenance costs.

RAETTS can perfectly solve the problems that paper mills are worried about, the maglev turbo blower will not fail due to frequent start-ups and shut-downs.

RAETTS maglev turbo blower relies on the magnetic field to suspend the bearing and maintain high-speed operation. There is no contact between the rotating shaft and the bearing during operation, and there will be no wear and failure. The maglev turbo blower is also equipped with UPS power to prevent sudden bearing damage due to power failure.

Therefore, to prevent malfunction, the RAETTS magnetic levitation centrifugal blower is the best choice.

In general, magnetic levitation blowers have the following excellent advantages:

- Good energy saving effect: compared with the old Roots blowers and multi-stage centrifugal blowers, the energy saving effect of maglev blowers is more than 30%, and can continue to save energy;

- Low noise and environmental protection: magnetic suspension turbo blower using suspension electric bearing, suspension without friction, low noise, no lubricating oil, more environmentally friendly;

- Low maintenance cost: the maglev turbo blower is simple in structure, unlike the traditional Roots blower, with heavy and mechanical failures, and high maintenance costs; The maglev turbo only needs to replace the filter element and filter cotton from time to time, and the maintenance cost is low.

- Good economic benefits: investment in a magnetic levitation blower in the wastewater production line can recover the cost of the machine in one to one and a half years, and the power saving is significant;

RAETTS can customize high-efficiency aerodynamic solutions for all paper mills according to project analysis, energy consumption calculation, site selection planning, piping layout, blower parameters, etc. The professional installation and after-sales teams nationwide can provide customers with high-quality and fast service at any time.

RAETTS has served many papermaking enterprises in Guangdong, Hunan, Hubei, Fujian and Liaoning Province over recent years. RAETTS maglev turbo blower uses the international advanced suspension bearing technology and semipermanent service life due to no contact parts, the quality is excellent. At the same time, it can realize the intelligent management of the factory blast and aeration system, which can help the paper-making enterprises save a lot of money, and is an excellent choice for papermaking enterprises to upgrading and reconstruction

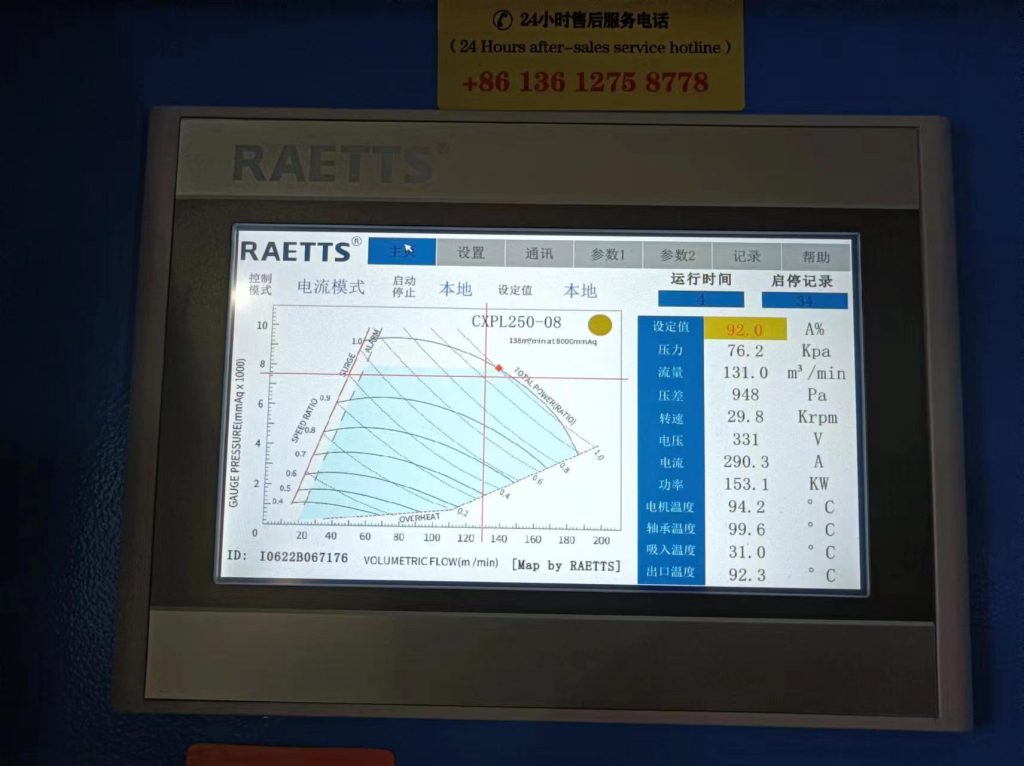

Jiangxi Liwen Paper.:Using a 185kW magnetic levitation turbo blower-CXPL250-08, the energy-saving effect is very obvious.

- RAETTS maglev turbo blower CXPL250-08 185kW

- RAETTS maglev turbo blower for wastewater treatment

- RAETTS maglev turbo blower for the paper industry