In the modern era of industrial development, the need for energy-efficient, high-performance, and environmentally friendly cooling solutions has never been more critical. Industries across the globe are seeking advanced technologies to optimize energy consumption and reduce operational costs while maintaining superior performance. RAETTS, a global leader in turbo blower manufacturing, has introduced the cutting-edge Precision Maglev Centrifugal Chiller, a breakthrough in advanced cooling technology. This innovative solution is redefining the standards of efficiency, sustainability, and precision in cooling systems.

What is a Precision Maglev Centrifugal Chiller?

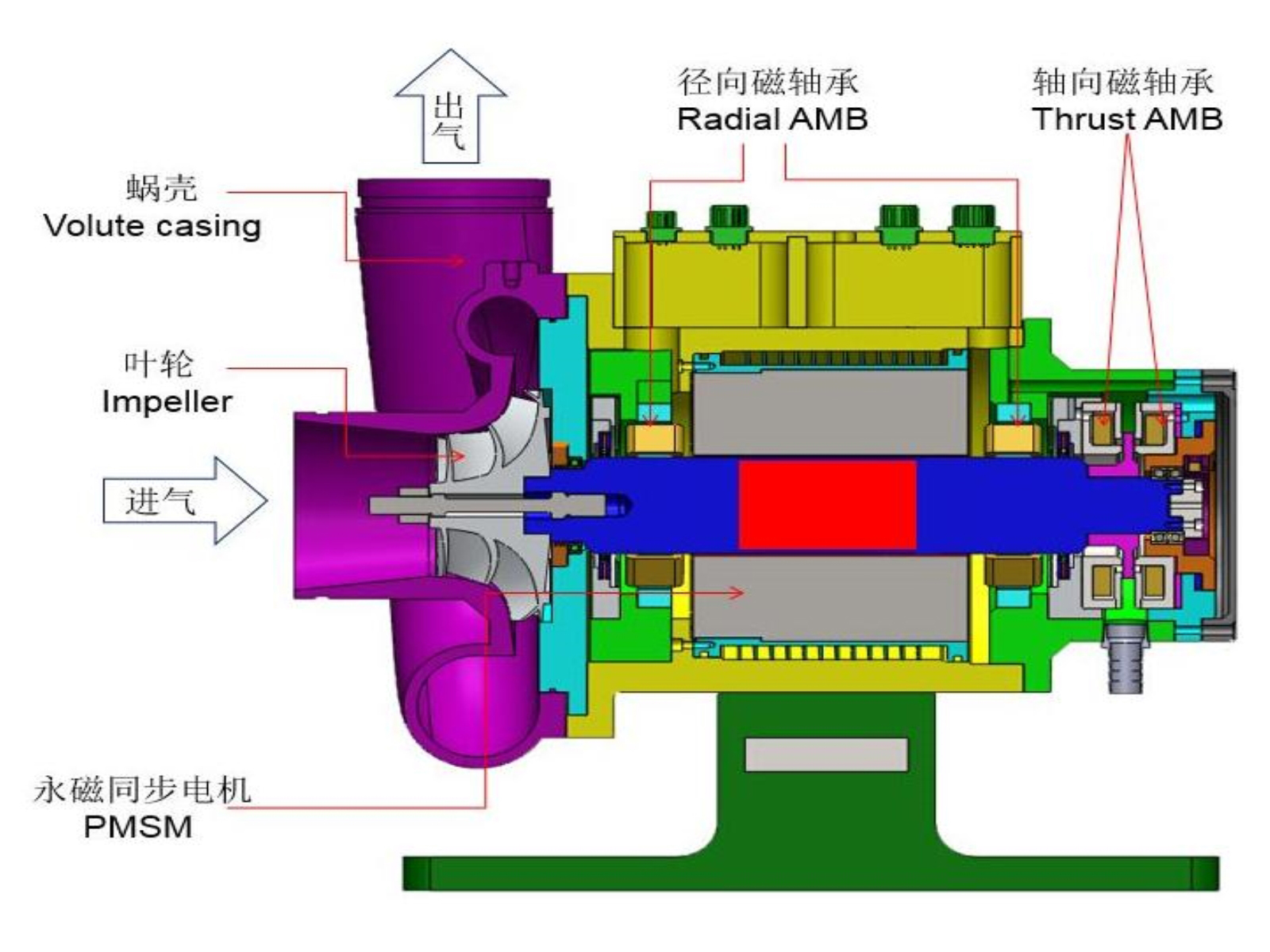

A Precision Maglev Centrifugal Chiller is a state-of-the-art cooling system that utilizes magnetic levitation (maglev) technology for its operation. Unlike traditional chillers that rely on mechanical bearings, the maglev centrifugal chiller uses magnetic fields to suspend and rotate the compressor shaft without physical contact. This eliminates friction, reduces wear and tear, and significantly enhances energy efficiency.

RAETTS has seamlessly integrated maglev technology with its expertise in turbo blower manufacturing to create a chiller that is not only efficient but also highly reliable and environmentally sustainable. The result is a game-changing cooling solution that meets the demands of industries ranging from data centers to pharmaceutical manufacturing and beyond.

Key Features of RAETTS Precision Maglev Centrifugal Chiller

1. Magnetic Levitation Technology

The core feature of the RAETTS Precision Maglev Centrifugal Chiller is its magnetic levitation technology. By eliminating mechanical bearings, the system achieves near-zero friction, resulting in unparalleled energy efficiency and operational longevity. The maglev compressor operates with precision, ensuring stable and reliable performance over extended periods.

2. High Energy Efficiency

RAETTS’ maglev chillers boast exceptional energy efficiency, with Integrated Part Load Value (IPLV) ratings significantly higher than traditional chillers. The chiller can adapt to varying load conditions, optimizing energy consumption and reducing electricity bills. This makes it an ideal choice for industries aiming to lower their carbon footprint.

3. Ultra-Quiet Operation

Thanks to the absence of mechanical bearings and the advanced aerodynamic design of the turbo blower, RAETTS Precision Maglev Centrifugal Chillers operate with minimal noise. This feature is particularly beneficial for noise-sensitive environments such as hospitals, research laboratories, and office buildings.

4. Compact and Lightweight Design

RAETTS has engineered its maglev chillers to be compact and lightweight, making them easy to install and maintain. The reduced footprint allows industries to maximize their operational space without compromising on cooling performance.

5. Environmentally Friendly Refrigerants

In line with global sustainability goals, RAETTS Precision Maglev Centrifugal Chillers use environmentally friendly refrigerants that comply with international standards. This ensures reduced greenhouse gas emissions and a lower environmental impact.

6. Advanced Control Systems

The chiller is equipped with intelligent control systems that allow real-time monitoring and precise adjustments. The user-friendly interface provides detailed insights into system performance, enabling proactive maintenance and troubleshooting.

Applications of RAETTS Precision Maglev Centrifugal Chiller

The versatility of the RAETTS Precision Maglev Centrifugal Chiller makes it suitable for a wide range of applications. Below are some industries where this advanced cooling solution is making a significant impact:

- Data Centers: With the exponential growth of data centers, efficient cooling is essential to prevent overheating and ensure uninterrupted operations. RAETTS maglev chillers provide reliable and energy-efficient cooling for these critical facilities.

- Pharmaceutical Manufacturing: Temperature control is crucial in pharmaceutical production to maintain product quality and safety. The precision and reliability of RAETTS maglev chillers make them an ideal choice for this industry.

- HVAC Systems: Commercial buildings, shopping malls, and office complexes benefit from the quiet and efficient operation of RAETTS maglev chillers, ensuring a comfortable environment for occupants.

- Food and Beverage Industry: Maintaining precise temperature levels is vital for food storage and processing. RAETTS chillers deliver consistent cooling performance to meet these requirements.

- Industrial Processes: From chemical processing to metal fabrication, RAETTS maglev chillers support various industrial applications by providing reliable cooling solutions.

The RAETTS Advantage: Why Choose RAETTS Precision Maglev Centrifugal Chiller?

As a renowned turbo blower manufacturer, RAETTS brings decades of experience and expertise to the development of its Precision Maglev Centrifugal Chillers. Here are some reasons why RAETTS stands out in the industry:

1. Innovation and Expertise

RAETTS is committed to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of industry trends and deliver cutting-edge solutions to its customers.

2. Proven Track Record

With a global presence and a diverse portfolio of successful projects, RAETTS has established itself as a trusted partner for industries worldwide. Its maglev chillers have been deployed in various sectors, delivering consistent performance and reliability.

3. Customer-Centric Approach

RAETTS prioritizes customer satisfaction by offering tailored solutions that meet specific requirements. The company provides comprehensive support, from system design and installation to maintenance and troubleshooting.

4. Commitment to Sustainability

RAETTS is dedicated to promoting sustainable practices and reducing environmental impact. Its maglev chillers are designed to minimize energy consumption and greenhouse gas emissions, contributing to a greener future.

Technical Specifications of RAETTS Precision Maglev Centrifugal Chiller

Below is a table summarizing the key technical specifications of RAETTS Precision Maglev Centrifugal Chillers:

| Parameter | Specification |

|---|---|

| Cooling Capacity | 100 – 2000 Tons |

| Compressor Type | Magnetic Levitation Centrifugal |

| Refrigerant | Eco-Friendly Options (e.g., R134a, R513A) |

| Energy Efficiency Ratio (EER) | Up to 11.5 |

| Noise Level | Less than 70 dB |

| Control System | Advanced PLC with Touchscreen Interface |

Conclusion: A New Era of Cooling Technology

The RAETTS Precision Maglev Centrifugal Chiller represents a significant leap forward in cooling technology. By combining magnetic levitation with advanced turbo blower design, RAETTS has created a solution that addresses the challenges of energy efficiency, reliability, and sustainability. Industries around the world are leveraging this innovative technology to enhance their operations, reduce costs, and contribute to environmental conservation.

As the demand for advanced cooling solutions continues to grow, RAETTS remains at the forefront of innovation, delivering products that redefine industry standards. The Precision Maglev Centrifugal Chiller is more than just a cooling system; it is a testament to RAETTS’ commitment to excellence and its vision for a sustainable future.

If you’re looking for a high-performance, energy-efficient, and environmentally friendly cooling solution, the RAETTS Precision Maglev Centrifugal Chiller is the ultimate choice. Contact RAETTS today to learn more about how this revolutionary technology can transform your operations.