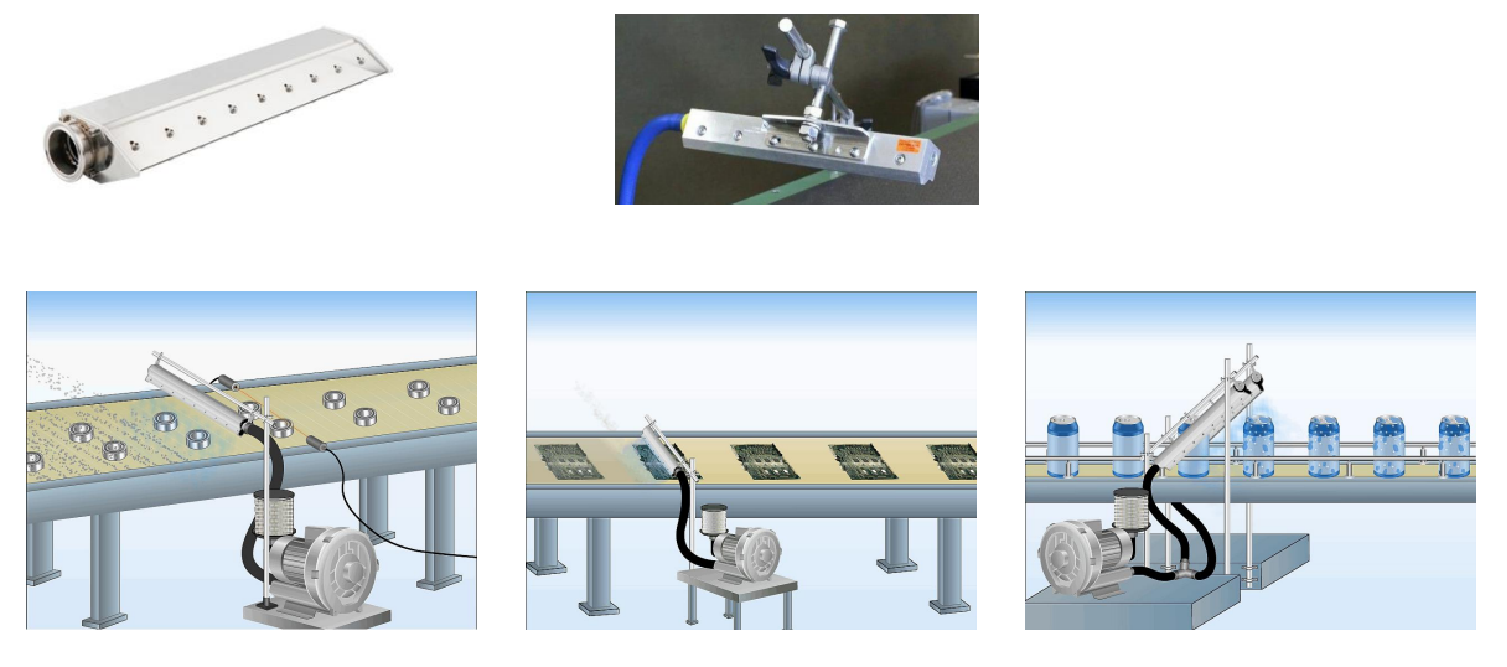

-Air knife

– Air knife is a device used to blow out strong and high-speed airflow to blow away dust, dry liquid objects, and cool down the temperature.

Application of air knife for hot-dip galvanized sheets

Classification of sheet galvanizing process:

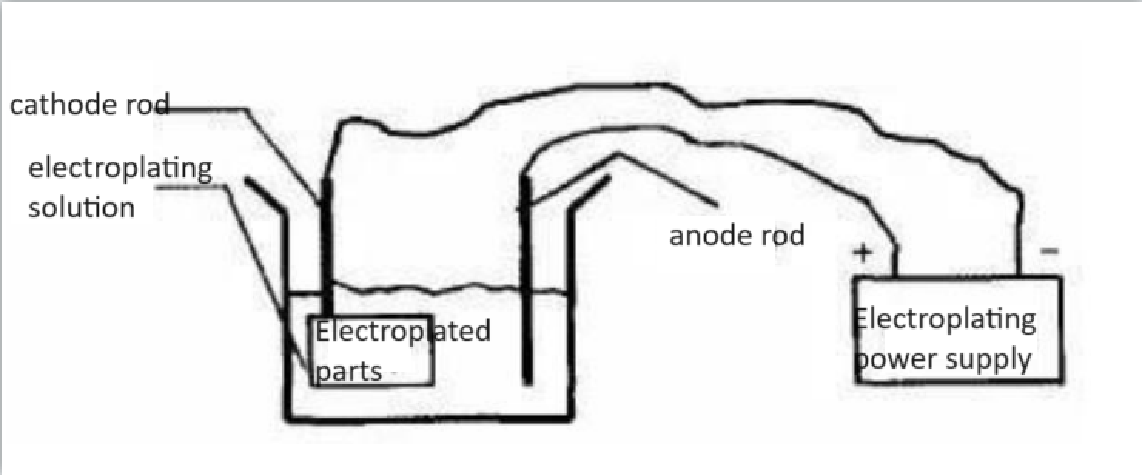

-cold galvanized:

– Also called electro-galvanizing, electrolytic equipment is used to degrease and pickle the pipe fittings and put them into a solution composed of zinc salts, and connect the negative electrode of the electrolytic equipment. A galvanized plate is placed opposite the pipe fittings and linked to the positive electrode of electrolytic equipment, then turn on the power, and use the directional movement of current flowing from the positive electrode to the negative electrode to deposit a layer of zinc on the steel plate. -The advantage is that this galvanized steel sheet has good process ability; but the coating is thin and its corrosion resistance is not as good as hot-dip galvanized sheet.

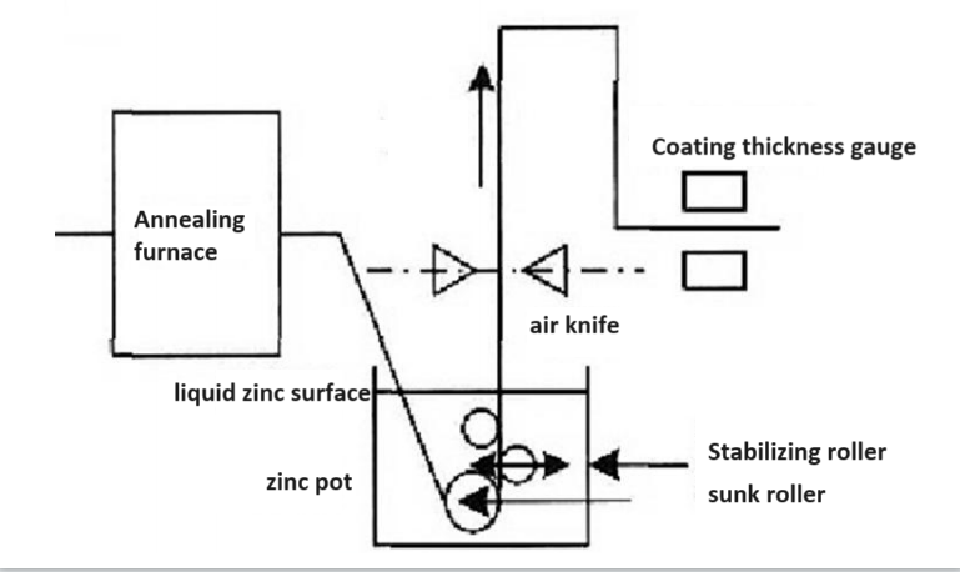

-Hot dip galvanized

– Also called hot-dip galvanizing.The process is metals such as steel, stainless steel, cast iron, etc. are immersed in molten zinc liquid at about 500°C, so that a zinc layer is attached to the surface of the steel plate for the purpose of anti-corrosion. -The advantages are good covering ability, dense galvanized layer and not easy to fall off; but the appearance is rougher than cold galvanized and has poor gloss.

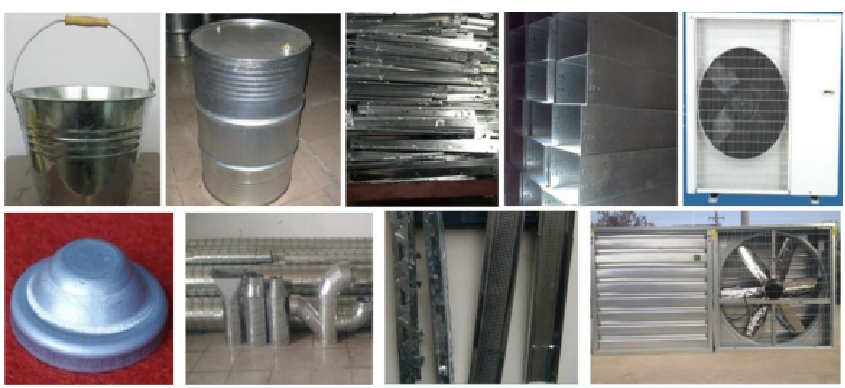

-Application of galvanized sheets

-Used in automobile manufacturing, refrigerated containers, construction industry, ventilation and heating facilities and furniture manufacturing, etc. -Construction industry: roofs, roof components, balcony panels, window sills, parking garages, rolling shutter doors, heaters, rainwater pipes, etc. -Household appliances: refrigerators, washing machines, switch cabinets, air conditioners, microwave ovens, toasters, copiers, vending machines, electric fans, vacuum cleaners, etc. -Furniture industry: lampshades, wardrobes, tables, bookshelves, counters, signs, medical equipment, etc. -Transportation industry: car ceilings, car shells, carriage panels, tractors, trams, containers, highway walls, ship bulkheads, etc. -Other color-coated steel sheets such as musical instrument casings, trash cans, billboards, clocks, photographic equipment, meters, etc. are based on hot-dip galvanized sheets, hot-dip galvanized sheets, electroplating, etc., and have been surface pre-treated.

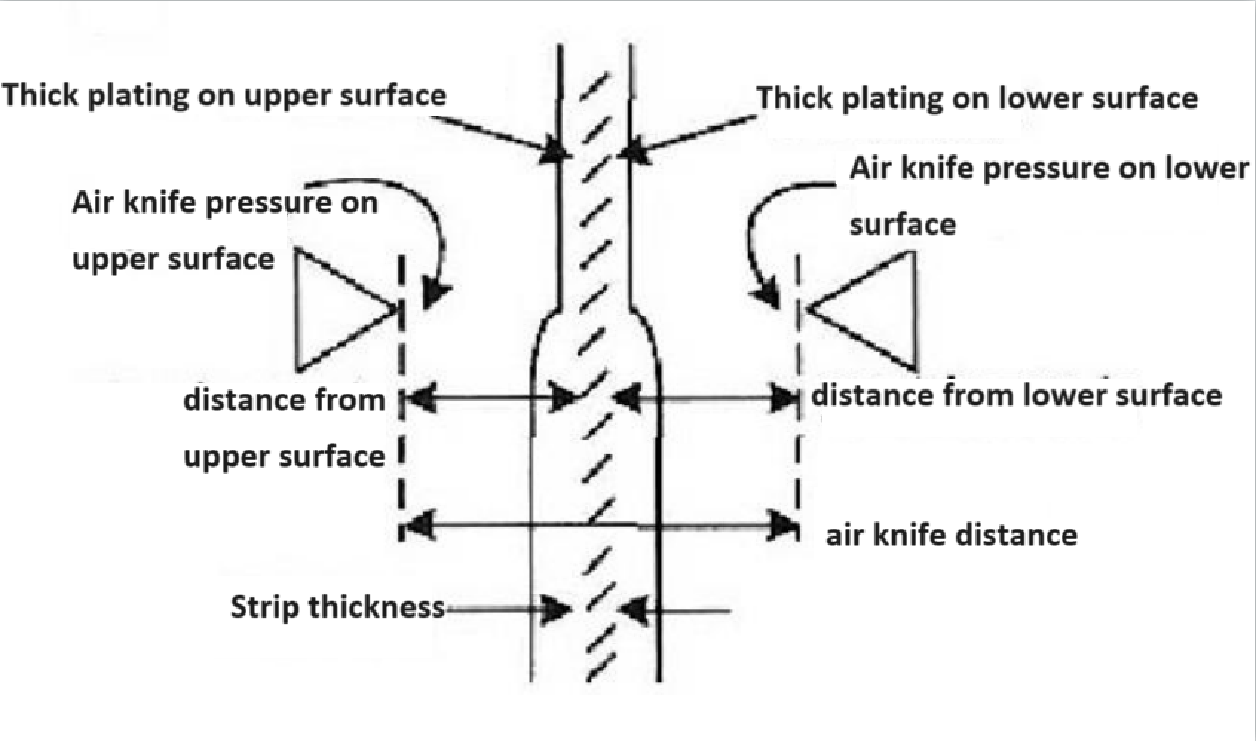

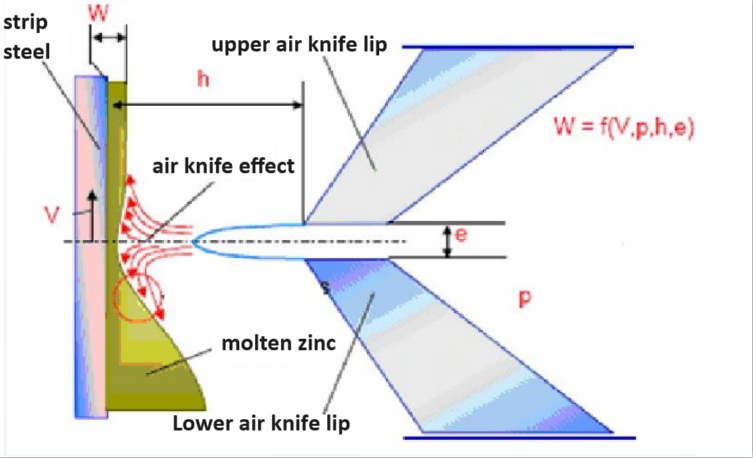

-The working principle of hot-dip galvanizing air knife

– Use a pair of nozzles that span the entire width of the strip to spray out a continuous knife-like flat airflow to scrape off the excess zinc liquid on the surface of the strip, leaving a uniform and appropriate amount of zinc layer on the surface of the strip. And let the excess zinc liquid return to the zinc pot.

-Thickness of galvanized layer

-General requirements:

| Parts and thickness/mm | Coating local thickness/um

mm |

Average coating thickness/um mm |

| Steel thickness>6 | 70 | 85 |

| Steel thickness 3-6 | 55 | 70 |

| Steel thickness 1.5-3 | 45 | 55 |

| Steel thickness <1.5 | 35 | 55 |

-Three factors that determine the thickness W of the galvanized layer:

-Air pressure P (generally the pressure is around 2barg)

-The horizontal distance h of the air knife

-Lip seam g

-Compressed air requirements for hot dip galvanized sheet industry:

-no oil -No liquid water

-No dust and impurities

-Customer site pictures

-Some reference pictures of hot-dip galvanized factory which need to use the low pressure air compressor:

-The air pressure range of the industrial air compressor which is used in hot-dip galvanized industry:1.5barg-4barg.

RAETTS low pressure gas air compressor used magnetic levitation bearing,which is totally oil-free.The pressure range if RAETTS oil free air compressor is 1.5barg-4barg,which is perfectly suitable for hot-dip galvanized industry.The cooling system of this compressed air systems adopts air cooling+inter-stage water cooling,which will enable the silent air compressor to work in high temperature area and summer time.Comparing with traditional screw air compressor,RAETTS maglev centrifugal air compressor don’t need to add oil for lubrication,don’t need to change the ball bearing and other components.The maintenance of this air machine is quite easy and economic,daily maintenance only need to change the air filter,which is very convenient for the end user.

Pls feel free to contact with RAETTS team if you need any further support regarding the maglev turbo compressor:sales@raettsgroup.com