RAETTS Products

Experts for air suspension and magnetic levitation technologies.

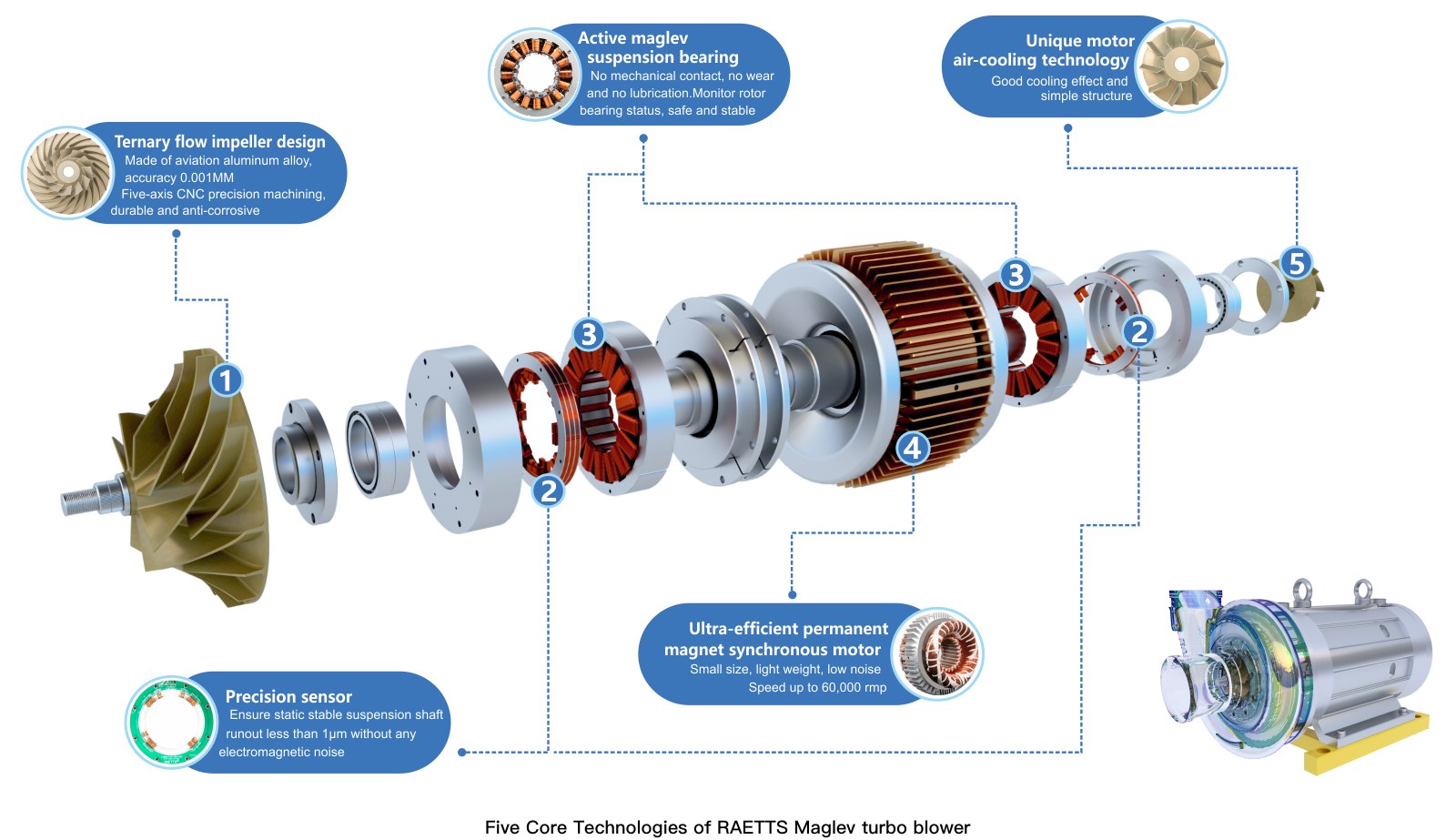

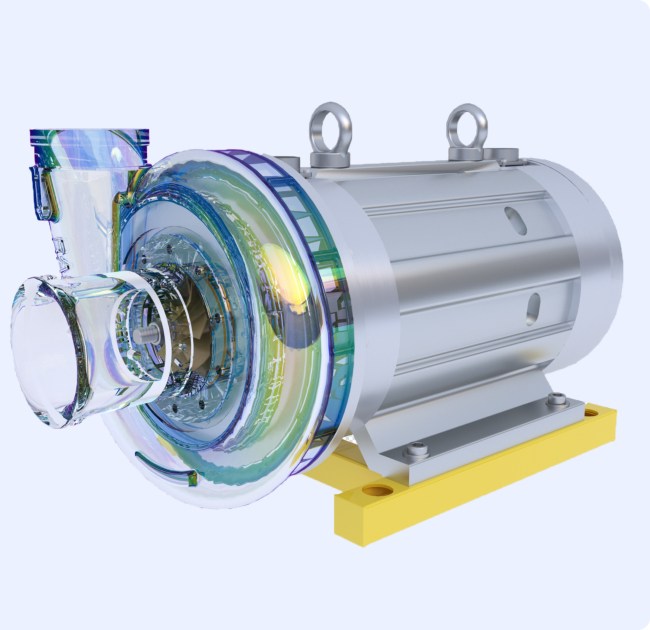

RAETTS maglev turbo blower(0.4-1.5bar,suitable for frequently start-stop working conditions)

RAETTS maglev turbo blower is R&D and designed by Germany advanced magnetic suspension technology, and adopts active levitation magnetic bearing, no friction, no lubricating oil required, no energy loss and service life more than 20 years, can save a lot of electricity and labor costs, return on investment ranges from 6 to 12 months.

RAETTS air bearing turbo blower is a brand-new concept blower, which integrates the main core technologies such as “air suspension bearing”, “permanent magnet ultra-high-speed motor”, “high-precision aviation-grade impeller”, and creates a new era of ultra-high efficiency ,low noise and low energy consumption. Since there is no physical friction between impeller and shaft, so it is no need to do maintenance for a long period, and the service life can reach semi-permanent. It has been certified as an “Energy Efficiency Star” equipment product by the state and won many honors.

MAGLEV TECHNOLOGY

Objects floating in the air are human dreams since ancient times, Magnetic suspension technique is a technology that uses magnetic force to overcome gravity to make objects levitate. Maglev turbo blower is a typical application of this technology.

WORKING PRINCIPLE

RAETTS Maglev turbo blower adopts a high-speed permanent magnet synchronous motor direct drive structure, which integrates the centrifugal impeller and the motor drive. lt detects the vibration of the rotor shaft and the space gap of the rotor shaft in real time through the built-in displacement sensor, and sends the obtained signal into the maglev bearing controller performs conditioning, analysis, and calculation to generate a control current, which is then input to the magnetic bearing winding coil to generate electromagnetic force, thereby realizing the suspension of the rotor shaft. RAETTS maglev turbo blower is equipped with maglev bearing, high-speed permanent magnet synchronous motors and high efficiency ternary flow impeller, and adopts a high-speed permanent magnet synchronous motor direct drive structure. High-efficiency inverter automatically adjusts the bearing speed in real time, realize automatic control and unattended. RAETTS maglev turbo blower adopts active levitation magnetic bearing, which is suspended before rotation after power on, no friction and no lubricating oil required. No energy loss due to the direct connection between the ternary flow impeller and the rotor, is a high-tech, green, energy-saving, and environmentally friendly product.

01

High speed permanent magnet synchronous motor (PMSM)

The motor efficiency up to 96%. Compared with other motors, it has the advantages of high power, high speed, small size, small power loss, compact in heat-proof structure, special design for high speed rotation and precise speed control.

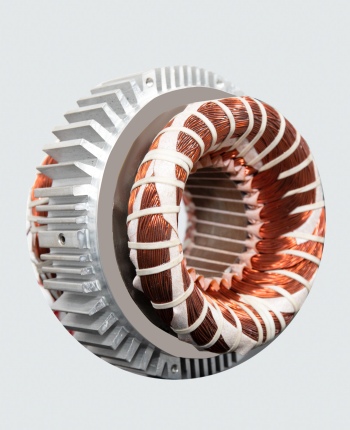

02

Magnetic suspension bearing

The magnetic suspension bearing is the core of the maglev turbo blower. The rotor is fixed between two radial magnetic bearings and two axial magnetic bearings. The position sensor will transmit the signal to the magnetic suspension bearing controller in real time.There is no physical contact between the rotor and the magnetic bearing, no lubricating oil required, low energy loss and high motor efficiency, and it is suitable for various working environments.

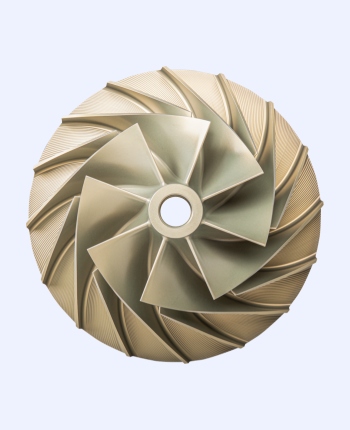

03

High efficiency ternary flow impeller

RAETTS establishes a scientific fluid flow model based on the ternary flow theory to ensure that the angle, number and shape of the blades are reasonable and efficient, reduce flow loss, ensure the smooth flow of air, uniform transmission, and ensure the best flow and efficiency.

04

Intelligent management system

In addition to the main control system, RAETTS Maglev turbo blower is also equipped with a global wireless communication intelligent management service system, which can monitor parameters such as speed, temperature, pressure, flow, and power through wireless communication technology to achieve unmanned.

05

Other key technologies+

Original cooling technology: Air-cooled model and water-cooled model, with good cooling effect.

Two-stage compression technology: two-stage impellers, and the pressure up to 150kPa;

Intelligent PLC control system: support RS485/RS232/THERNET.

Advantage

Relying on the leading blower energy-saving technology in the world,RAETTS maglev turbo blower can save energy more than 30%,comparing with traditional blowers;more than 5% comparing with the same specifications blower of other brands.

Applications case sharing

Project Name: Dangwa Sewage Treatment Plant in Linxiang District, Lincang City, Yunnan Province,China

Before the renovation of the project: the use of traditional centrifugal blowers, high energy consumption, high noise and high maintenance costs

After the renovation of the project: 3sets of RAETTS magnetic turbo blower CXPL150-08 110kw

Main parameters: flow rate 84m 3/min,pressure 80kPa

Energy saving effect: about 30%

Annual electricity saving: 3sets of magnetic turbo blowers save about 160,000$ electricity cost a yearPayback cycle: estimated one year

Project introduction

The sewage treatment plant in Linxiang District, Yunnan Province is located next to National Highway 214, 11 kilometers north of Lincang City, covering a total area of about 10.54 acres. The total investment of the first phase of the sewage plant is more than 13 million dollar. The total length of the pipeline network is 25.36 kilometers, and the service area is 22.85 square kilometers. The service population It is 195,300 people. The first phase passed the acceptance of the environmental protection department on June 28, 2010, and officially started operation on July 1, 2010. It adopts the CASS secondary biological advanced treatment process, and the effluent implements the national first-level B standard. The designed treatment capacity is 25,000 tons per day.

Linxiang District Sewage Treatment Plant Upgrading and Phase II Expansion Project is located in the Linxiang District Sewage Plant of Lincang City. The total investment of this project is about 10.5 million dollar, the treatment scale is 25,000 m³ per day, and SBR plus advanced treatment technology is adopted. The factory water implements the national first-class A standard. The project started construction on December 30, 2020, and the main body and equipment installation of the construction party is scheduled to be completed on September 28, 2021, and it will be put into trial production and operation on October 23, 2021. The total treatment scale of the current sewage plant will be increased to 50,000 tons per day, and the effluent will be upgraded from the national GB18918-2002 Class 1 B standard to GB18918-2002 Class 1 A standard.

The sewage treatment plant in Linxiang District used to use traditional centrifugal blowers for blowing and aerating, which consumes a lot of energy, makes big noise, has oil pollution, and has high maintenance costs. After researching and understanding the status and needs of the project, RAETTS professional technicians selected 3 sets of conventional high-pressure magnetic turbo blower (110kW) for the plant to meet the needs of various working conditions and achieve the purposes of good energy saving, noise reduction and low maintenance cost.

Customer Reviews

RAETTS magnetic bearing blower have significant energy-saving and consumption-reducing effects.The air blower is environmentally friendly and low-noise. The noise meet standards, avoiding complaints and rectifications. RAETTS magnetic turbo blower are also suitable for frequent start-stop operating conditions without damaging bearings; Moreover,RAETTS maglev turbo blower adopts intelligent control to realize unattended operation, saving more labor costs.

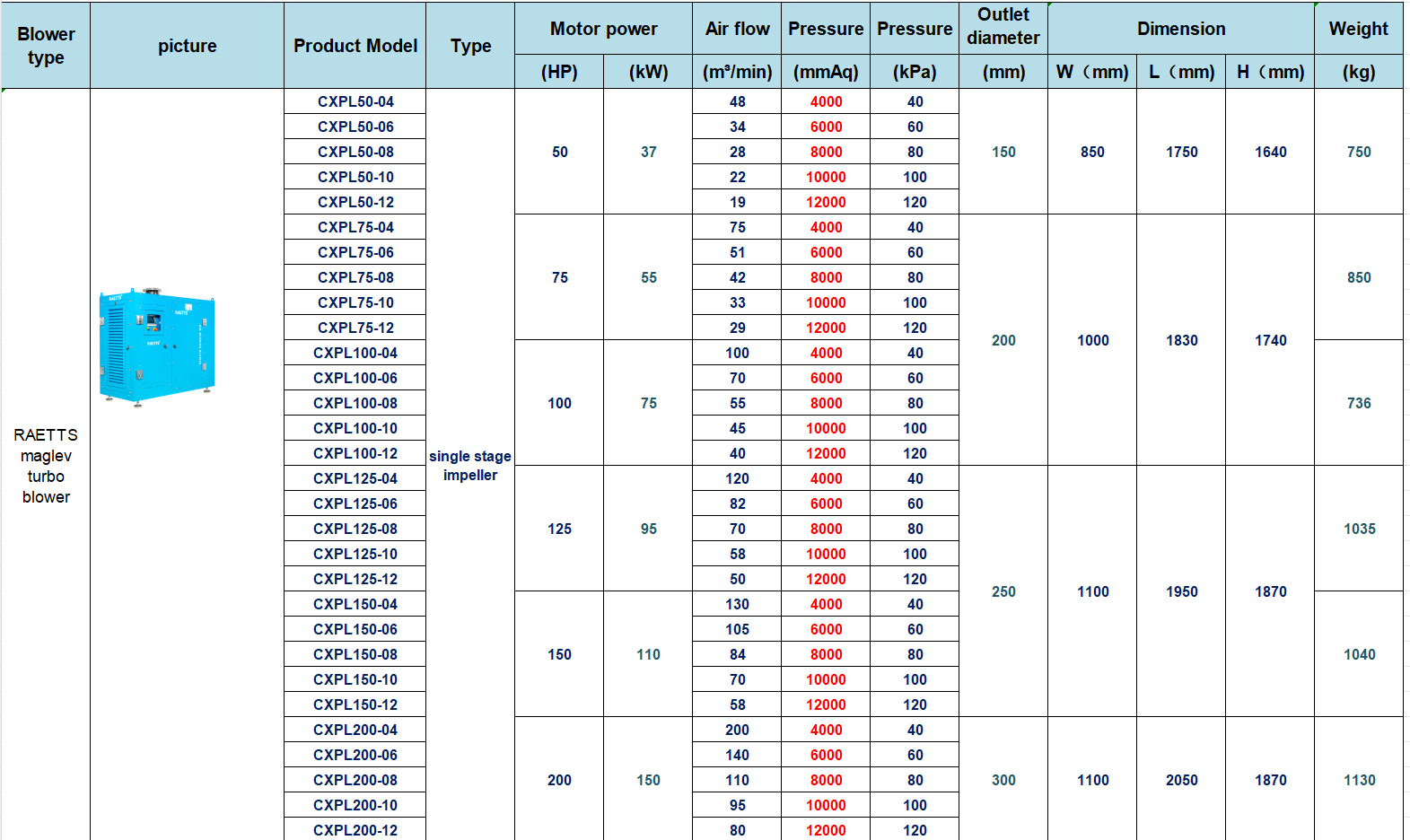

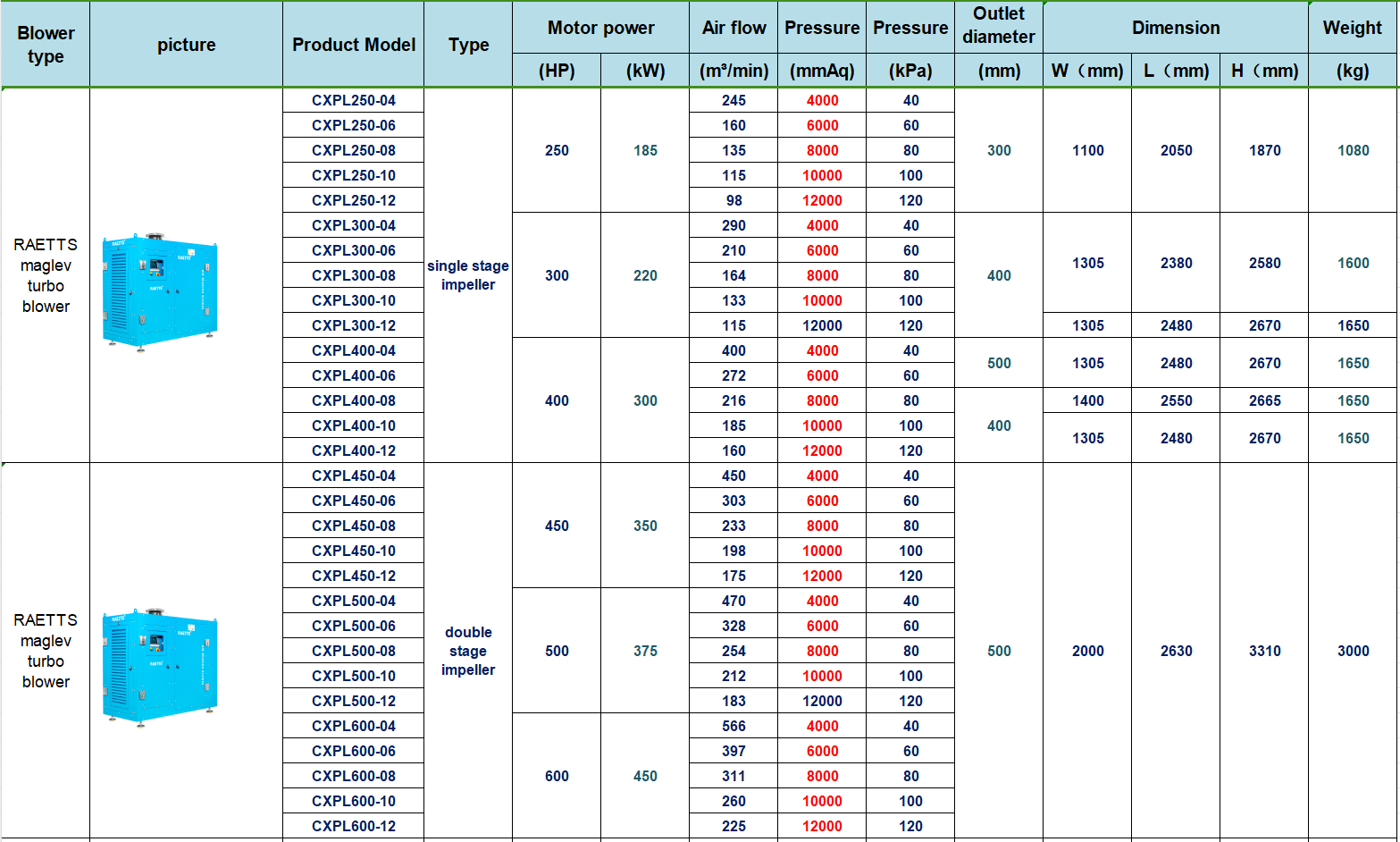

Selection parameters table

RAETTS provides high efficiency and energy-saving system solutions for our global customers,contributing to achieve the goal of carbon peaking and carbon neutrality.

For more information,feel free to click here to submit your request,our professional team will contact you soon

RAETTS High-Tech Park No.3,Juyuan Second Road.Dongguan City,Guangdong Province, China

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)

BelPragma LLC

Address: Republic of Belarus, Minsk, st. Amuratorskaya, 4, office 214

RAETTS RUS LLC

Address: Moscow, Elektrozavodskaya st., 24/1

Phone: +7 (495) 767-35-35

Mail: sales@raetts.ru

ENCOTEC Co.,Ltd. Add: 71/296 Soi.Ramkhamhaeng 164,Ramkhamhaeng Rd.,Minburi,Bangkok 10510,Thailand

T&T Pacific Sdn Bhd Add:No.31, Jalan PJU 3/49,Sunway Damansara,47810 Petaling Jaya,Selangor Darul Ehsan

Add:21 Center Drive, Hillsdale, NJ 07642

ASAP Servicios Técnicos Add:Calle Zinc 1, Nave A,28770 Colmenar Viejo, Madrid (Spain)

Adresse : 80 Rue Isabelle Eberhardt, 34000 Montpellier.

Telephone: 0033(0)652678173

PRODUCTS

CONTACT US

Asis HQ:Building 1, No. 3, Juyuan Second Road, Shangtun, Liaobu Town,Dongguan City, Guangdong Province,China

Europe HQ:

NeumarktstraBe 17,32052, Herford, Germany(R&D,Production&Sales)

Send In Inquiry