In the world of industrial applications, energy efficiency and operational flexibility are paramount. Turbo blowers play a critical role in various sectors, offering the necessary air flow and pressure for processes such as wastewater treatment, pneumatic conveying, and aeration. RAETTS, a leading manufacturer of turbo blowers, has been at the forefront of innovation, particularly in the development and implementation of variable speed control technology. This article delves into the myriad benefits that variable speed control brings to turbo blower systems, highlighting how RAETTS is revolutionizing industrial efficiency.

Understanding Turbo Blower Systems

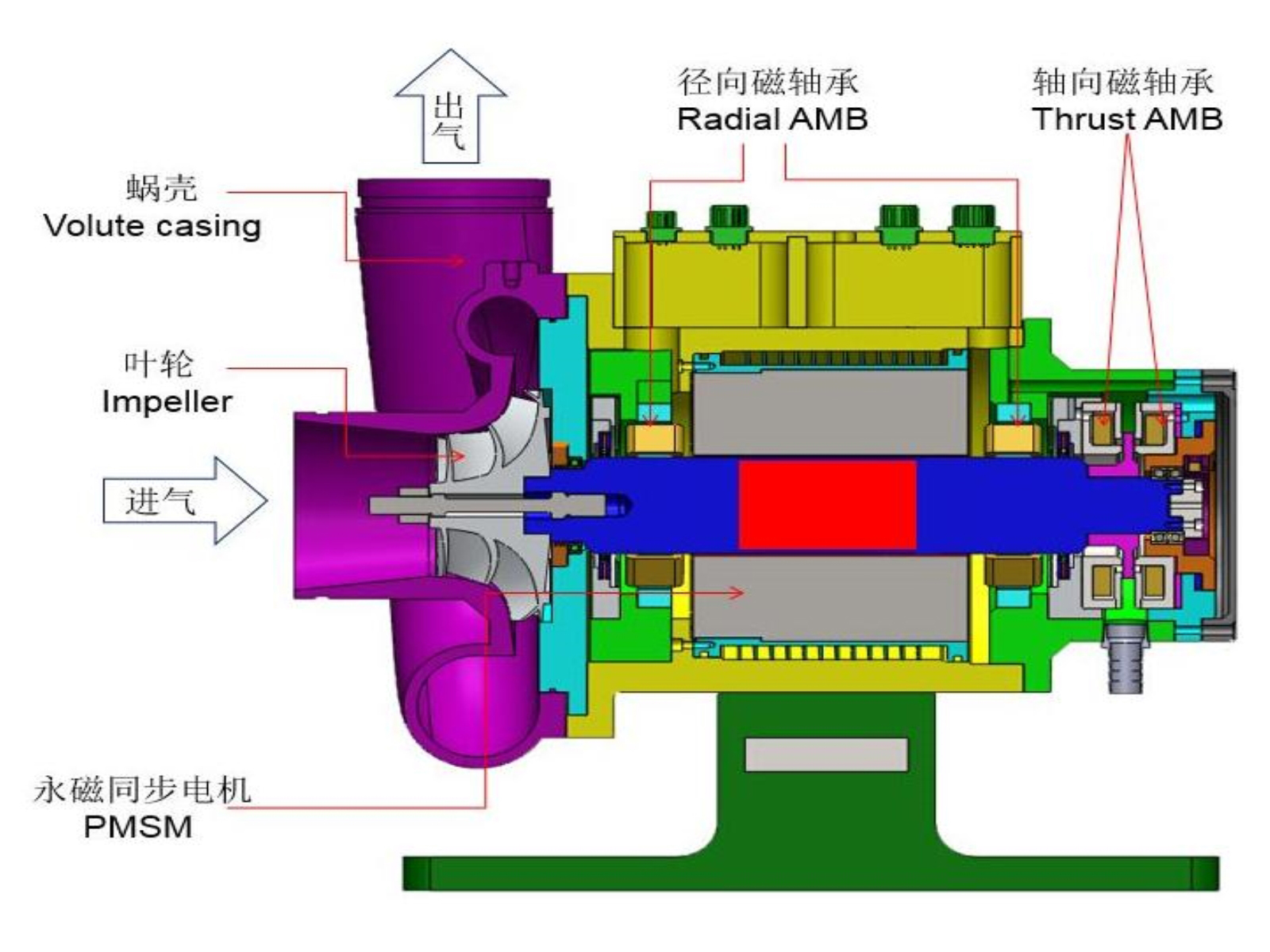

Turbo blowers are mechanical devices that increase the pressure of air or gas by using a rotating impeller. They are widely used in industries that require high volumes of air at varying pressures. Traditionally, these systems operated at a fixed speed, which often led to inefficiencies, especially when the demand for air fluctuated. This is where variable speed control becomes a game-changer.

What is Variable Speed Control?

Variable speed control allows the blower to adjust its speed based on the real-time demand for air. This is achieved through the use of advanced electronics and control systems that monitor the process requirements and adjust the motor speed accordingly. By doing so, it ensures that the blower operates at optimal efficiency, reducing energy consumption and wear and tear on the equipment.

Advantages of Variable Speed Control in Turbo Blowers

1. Enhanced Energy Efficiency

One of the most significant benefits of variable speed control is its ability to enhance energy efficiency. By adjusting the blower speed to match the exact demand, energy wastage is minimized. RAETTS turbo blowers with variable speed control can reduce energy consumption by up to 30% compared to traditional fixed-speed systems. This not only lowers operational costs but also contributes to a reduced carbon footprint.

2. Improved Process Control

Variable speed control provides precise control over the airflow and pressure, which is crucial for processes that require specific conditions. This level of control ensures that the process operates within the desired parameters, improving product quality and consistency. For industries like wastewater treatment, this means better aeration control, leading to more efficient treatment processes.

3. Reduced Mechanical Stress

Operating a blower at a constant high speed can lead to increased wear and tear on mechanical components. Variable speed control mitigates this issue by allowing the blower to operate at lower speeds when full capacity is not needed. This reduces mechanical stress, prolonging the lifespan of the equipment and decreasing maintenance costs.

4. Noise Reduction

Noise pollution is a common concern in industrial settings. Turbo blowers operating at high speeds generate significant noise, which can be disruptive and harmful over time. Variable speed control helps reduce noise levels by allowing the blower to run at lower speeds when full capacity is unnecessary. This creates a quieter and more comfortable working environment.

5. Flexibility and Adaptability

Industries often face varying demands for air flow and pressure. Variable speed control provides the flexibility to adapt to these changes seamlessly. RAETTS turbo blowers with variable speed technology can quickly adjust to new process requirements, ensuring optimal performance regardless of changes in demand.

RAETTS: Pioneering Innovation in Turbo Blower Technology

RAETTS has established itself as a leader in the turbo blower industry, thanks to its commitment to innovation and quality. The company’s focus on integrating variable speed control into its products has set a new standard for efficiency and performance.

Advanced Control Systems

RAETTS turbo blowers are equipped with state-of-the-art control systems that allow for precise monitoring and adjustment of blower speed. These systems are designed to be user-friendly, providing operators with easy access to performance data and control settings. This ensures that the blowers can be optimized for any application, maximizing efficiency and effectiveness.

Custom Solutions for Diverse Applications

Recognizing that different industries have unique requirements, RAETTS offers customized solutions tailored to specific applications. Whether it’s wastewater treatment, chemical processing, or pneumatic conveying, RAETTS turbo blowers with variable speed control can be configured to meet the precise needs of any operation.

Commitment to Sustainability

RAETTS is dedicated to promoting sustainability in the industries it serves. By enhancing the energy efficiency of its turbo blowers through variable speed control, the company helps its clients reduce their environmental impact. This commitment to sustainability is reflected in RAETTS’ continuous efforts to innovate and improve its products.

Case Studies: Real-World Applications of RAETTS Turbo Blowers

To illustrate the tangible benefits of variable speed control in turbo blowers, let’s explore some real-world applications where RAETTS has made a significant impact.

Wastewater Treatment Plant in Europe

A major wastewater treatment plant in Europe implemented RAETTS turbo blowers with variable speed control to optimize its aeration process. The plant experienced a 25% reduction in energy consumption, leading to substantial cost savings. Additionally, the improved process control resulted in better treatment efficiency and compliance with environmental regulations.

Chemical Manufacturing Facility in Asia

A chemical manufacturing facility in Asia faced challenges with fluctuating demand for air in its processes. By integrating RAETTS turbo blowers with variable speed control, the facility achieved greater flexibility and adaptability, ensuring consistent product quality. The reduced mechanical stress also led to a decrease in maintenance costs and downtime.

Conclusion

Variable speed control in turbo blower systems offers numerous benefits, from enhanced energy efficiency and improved process control to reduced mechanical stress and noise levels. RAETTS, a leader in turbo blower technology, is at the forefront of this innovation, providing advanced solutions that meet the diverse needs of modern industries. By choosing RAETTS turbo blowers with variable speed control, businesses can achieve greater operational efficiency, cost savings, and sustainability.

As industries continue to evolve and prioritize efficiency and sustainability, the demand for advanced technologies like variable speed control in turbo blowers will only grow. RAETTS remains committed to leading this evolution, ensuring that its clients have access to the most efficient and reliable solutions available.

In summary, the integration of variable speed control in turbo blower systems is not just a technological advancement; it is a strategic move towards a more sustainable and efficient future. With RAETTS at the helm, industries can confidently embrace this technology, knowing they are supported by a company dedicated to excellence and innovation.