In today’s industrial landscape, the demand for efficient and reliable machinery is ever-growing. One such critical component is the turbo blower, an essential device used in a variety of applications, from wastewater treatment to pneumatic conveying. RAETTS, a leading turbo blower manufacturer, has been at the forefront of innovation, ensuring that their products not only meet but exceed industry standards. This article delves into the intricacies of turbo blower cooling systems, exploring their functionality and significance in modern industrial applications.

Understanding Turbo Blowers

Turbo blowers are high-speed devices designed to move air or gas with the help of a rotating impeller. Unlike traditional blowers, turbo blowers operate at higher efficiencies and can deliver a greater volume of air at higher pressures. This makes them ideal for applications that demand continuous and robust airflow.

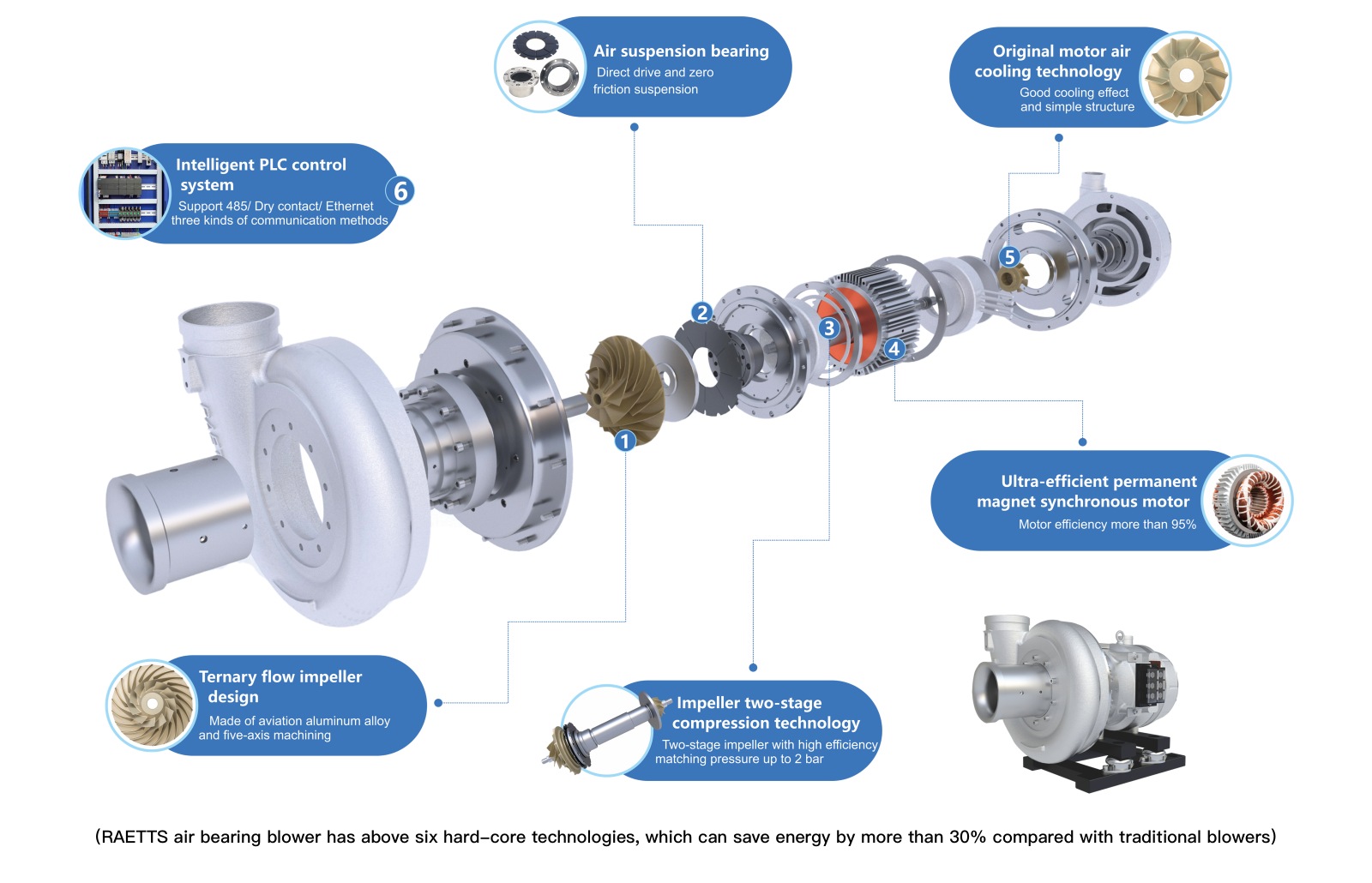

The design of a turbo blower is such that it minimizes energy consumption while maximizing output. This is achieved through advanced aerodynamic designs, precision engineering, and the use of high-quality materials. As a result, turbo blowers are not only energy-efficient but also have a longer operational life, reducing the need for frequent maintenance and replacements.

The Role of Cooling Systems in Turbo Blowers

A critical aspect of turbo blower operation is the management of heat. The high-speed rotation of the impeller generates significant amounts of heat, which, if not properly managed, can lead to equipment failure. This is where cooling systems come into play.

Cooling systems are integral to the operation of turbo blowers, ensuring that the device operates within safe temperature limits. By dissipating excess heat, cooling systems prevent overheating, thereby enhancing the reliability and longevity of the blower.

RAETTS has pioneered several cooling technologies that have set new benchmarks in the industry. These technologies not only improve the performance of the turbo blowers but also contribute to their sustainability by reducing energy consumption and emissions.

Types of Cooling Systems

There are several types of cooling systems used in turbo blowers, each with its unique advantages and applications. The choice of cooling system depends on various factors, including the application, environmental conditions, and specific requirements of the operation.

- Air Cooling: This is the most common type of cooling system used in turbo blowers. It involves the use of ambient air to dissipate heat from the blower. Air cooling systems are simple, cost-effective, and require minimal maintenance. However, their efficiency can be affected by environmental conditions, such as high ambient temperatures.

- Water Cooling: Water cooling systems use water as the medium to transfer heat away from the turbo blower. These systems are more efficient than air cooling, especially in high-temperature environments. However, they require a continuous supply of water and are more complex to maintain.

- Oil Cooling: In oil cooling systems, oil is used to absorb and dissipate heat. These systems are typically used in heavy-duty applications where high levels of heat are generated. Oil cooling provides excellent thermal stability and is highly efficient, but it requires regular maintenance to ensure optimal performance.

Why Cooling Systems Matter

The importance of cooling systems in turbo blowers cannot be overstated. Proper cooling is essential for maintaining the operational efficiency and reliability of the blower. Without an effective cooling system, a turbo blower is prone to overheating, which can lead to mechanical failures, reduced efficiency, and increased operational costs.

Cooling systems also play a crucial role in extending the lifespan of turbo blowers. By preventing overheating and reducing thermal stress, these systems help maintain the structural integrity of the blower components, ensuring that they perform optimally over their intended lifespan.

Moreover, efficient cooling systems contribute to energy savings. By maintaining optimal operating temperatures, these systems ensure that the blower operates at peak efficiency, reducing energy consumption and lowering operational costs. This is particularly important in industries where energy costs constitute a significant portion of operational expenses.

RAETTS: Leading the Way in Turbo Blower Technology

RAETTS has established itself as a leader in the turbo blower industry, thanks to its commitment to innovation and quality. The company’s products are renowned for their efficiency, reliability, and advanced features, making them the preferred choice for industries worldwide.

One of the key factors behind RAETTS’ success is its focus on research and development. The company invests heavily in developing new technologies and improving existing ones, ensuring that its products remain at the cutting edge of the industry. This dedication to innovation has resulted in a range of turbo blowers that are not only highly efficient but also environmentally friendly.

RAETTS’ cooling systems are a testament to the company’s commitment to excellence. By incorporating advanced cooling technologies into their turbo blowers, RAETTS has set new standards for performance and reliability in the industry. These systems are designed to operate under the most demanding conditions, providing consistent and reliable performance while minimizing energy consumption and environmental impact.

Applications of RAETTS Turbo Blowers

RAETTS turbo blowers are used in a wide range of applications across various industries. Some of the key applications include:

- Wastewater Treatment: Turbo blowers are essential in wastewater treatment plants, where they are used to supply air for aerobic biological processes. RAETTS turbo blowers provide the efficiency and reliability needed to ensure optimal treatment performance.

- Pneumatic Conveying: In industries such as food processing and pharmaceuticals, turbo blowers are used to transport materials through pneumatic conveying systems. RAETTS blowers deliver the high airflows and pressures required for efficient material handling.

- HVAC Systems: Turbo blowers are used in heating, ventilation, and air conditioning (HVAC) systems to maintain indoor air quality and comfort. RAETTS blowers offer the performance and efficiency needed to ensure effective climate control.

- Power Generation: In power plants, turbo blowers are used to supply air for combustion processes, ensuring efficient and clean energy production. RAETTS blowers are designed to meet the rigorous demands of the power generation industry.

Conclusion

Turbo blower cooling systems are a critical component of modern industrial applications. They play a vital role in ensuring the efficiency, reliability, and longevity of turbo blowers, making them an indispensable part of many operations. RAETTS, as a leading manufacturer, has set the standard for turbo blower technology, offering products that deliver exceptional performance and sustainability.

As industries continue to evolve and demand more efficient and reliable equipment, the importance of advanced cooling systems in turbo blowers will only grow. RAETTS remains committed to innovation and excellence, ensuring that its products continue to meet the needs of its customers and contribute to a more sustainable and efficient industrial landscape.

In summary, understanding the workings and importance of turbo blower cooling systems is crucial for anyone involved in industries that rely on these devices. By choosing RAETTS turbo blowers, businesses can be assured of top-quality products that deliver unmatched performance and reliability, backed by a company that is dedicated to pushing the boundaries of technology and sustainability.