In recent years, more and more companies have adopted air suspension blowers to replace Roots blowers in standard improvement and transformation. So why can air suspension blowers replace Roots blowers?

What are the advantages of turbo blowers? According to the survey, the following points are found:

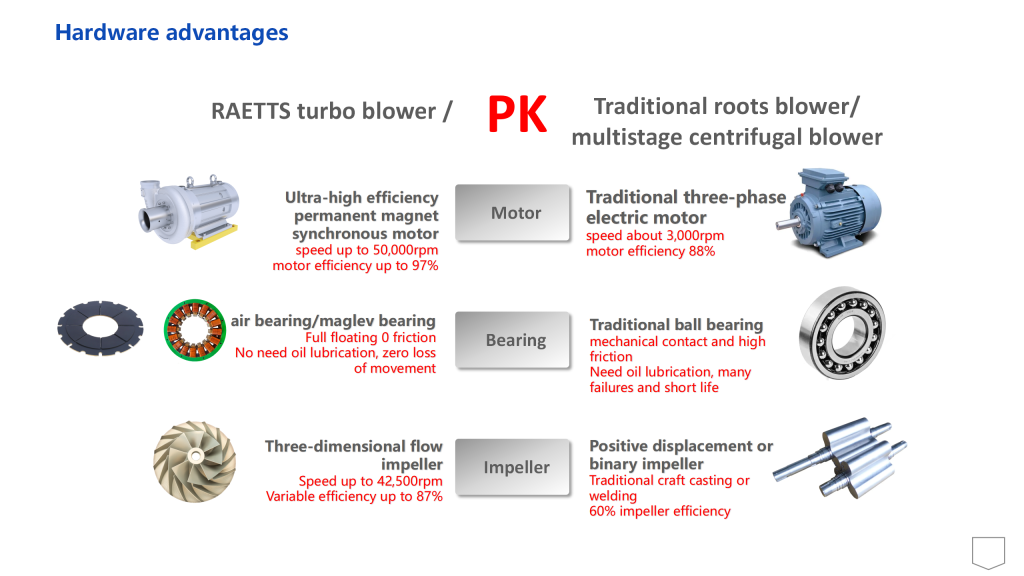

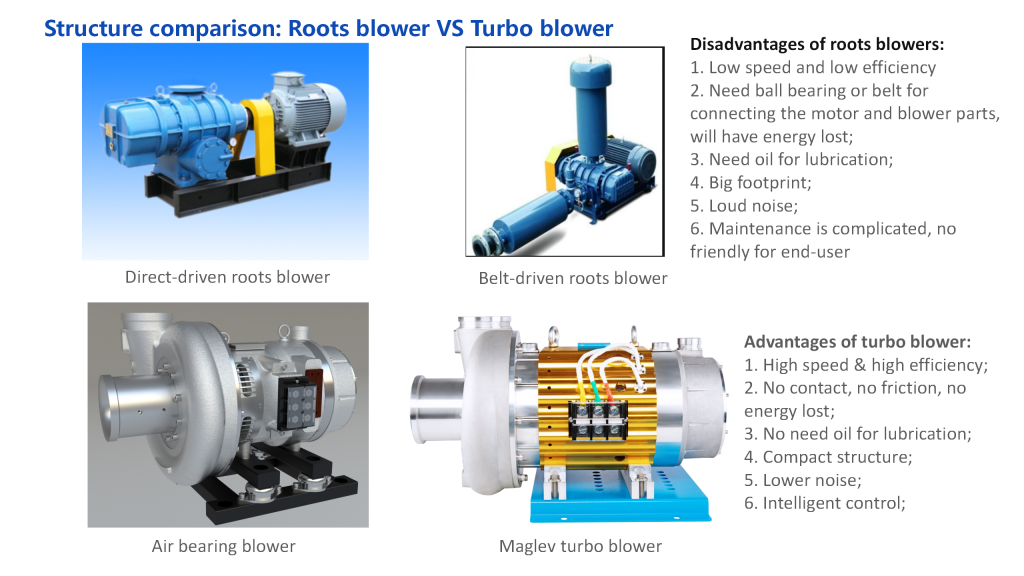

- Stable operation: The air bearing blowersuses air bearings, which have extremely low friction coefficients, allowing the blowersto operate stably for a long time and reducing downtime for maintenance. Roots blowers vibrate greatly during operation, have high maintenance costs and have a relatively short lifespan.

- Low noise: When the air suspension blower is running, the noise is low and the impact on the environment is small, while the noise of the Roots blower is relatively high.

- High efficiency and energy saving: Air bearing blower using air levitation technology, can reduce the heat generated by friction, improve the efficiency of the blower, so as to achieve energy saving effect. In contrast, the efficiency of Roots blower is low and the energy consumption is large.

- Compact structure: The air bearing blower is compact, occupies small space, and is easy to install and maintain. And Roots blower is large, installation and maintenance needs more space.

- Wide range of applications: air bearing blowers can not only be used in the traditional field of ventilation, but also can be used in modern industry, environmental protection, chemical, metallurgy, medical and other fields. Roots blowers are more suitable for some traditional areas.

In summary, air suspension blowers have the advantages of stable operation, low noise, high efficiency and energy saving, compact structure, and wide range of applications. They can meet the ventilation needs of different industries and places, and therefore can replace Roots blowers.