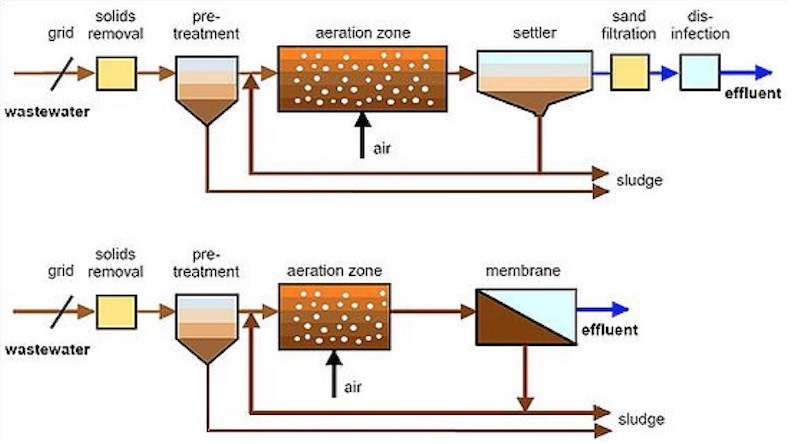

SBR is the abbreviation of sequential batch activated sludge process. It is an activated sludge wastewater treatment technology that operates according to the aeration method. Its main feature is seated and intermittent operation. The core of SBR technology is the SBR reaction tank, which integrates functions such as homogenization, primary sedimentation, biodegradation, and secondary sedimentation into one tank without a sludge return system.

It is especially suitable for occasions with insufficient construction space, intermittent discharge and large flow changes. The SBR process is widely used in the treatment of coal chemical wastewater in China. It mainly includes five steps: water inlet, reaction, precipitation, drainage and idle. The SBR process uses intermittent aeration. In order to ensure the aeration effect of each SBR reactor, one SBR reactor is often equipped with one blower for aeration operations.

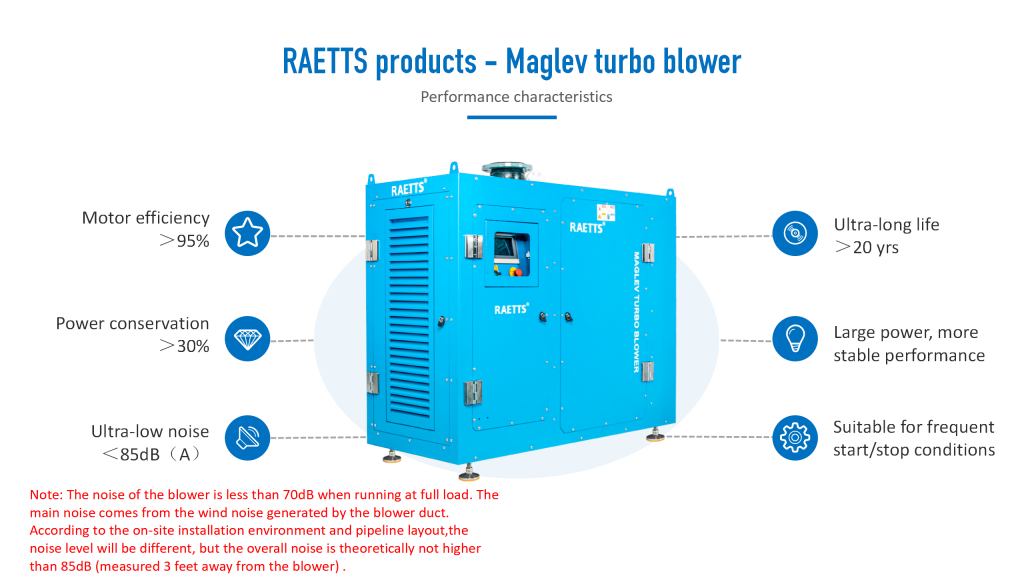

As a new type of energy-saving blower, the maglev turbo blower can save 30% to 50% of electricity compared with traditional Roots blowers and multi-stage centrifugal blowers. In recent years, it has been widely used in sewage treatment aeration processes. Aeration in the SBR process requires intermittent aeration, which means the blower needs to be started and stopped frequently. Traditional blowers can easily damage the bearings after frequent starts and stops, affecting performance and lifespan.

RAETTS maglev turbo blower uses magnetic levitation bearings. When starting, the rotor first levitates and then rotates. There is no friction and frequent starts and stops have no impact. It is especially suitable for aeration in the SBR process.

As air bearing blowers, when the air blower rotor rotates at high speed, it will produce a dynamic pressure effect on the surface of the rotor and the foil bearing, forming a high-pressure air film to float the rotor. At low speeds, there will be friction, and frequent starts and stops will cause certain damage and Influence. Therefore, the common blower in the SBR process is the maglev turbo blower.